The processing steps for green tea are mainly five: picking, withering, fixation, rolling, drying, and packaging. Among these, fixation is the key step in green tea processing.

The Process of Making Green Tea

1. Picking

Picking involves the process of harvesting the tea leaves. There are strict standards for picking, including the maturity and uniformity of the shoots and leaves, as well as the time of picking, which are all critical factors that determine the quality of the tea.

2. Withering

After fresh leaves are picked, they are spread out on clean surfaces to a thickness of about 7–10 centimeters. The withering time is generally 6–12 hours, during which the leaves should be turned appropriately. When the moisture content reaches 68%–70%, and the leaves become soft and emit a fragrant aroma, they are ready for the fixation stage. It is crucial to maintain the appropriate moisture level: too low and the leaves will dry out and become flavorless; too high and the accumulation of water can result in a bitter taste.

3. Fixation (Killing the Green)

Fixation is a critical step in green tea processing. It involves applying high temperatures to evaporate moisture from the leaves, deactivate enzyme activity, prevent enzymatic oxidation, and cause certain chemical changes in the leaf's contents. This forms the characteristic qualities of green tea, preserving its color and flavor.

If the temperature during fixation is too low, polyphenols undergo enzymatic reactions, resulting in red stems and leaves. Conversely, if the temperature is too high, chlorophyll is destroyed, causing the leaves to turn yellow or develop burned edges and spots, lowering the quality of the tea. For different grades and seasons of fresh leaves, the duration and temperature of fixation vary. It is essential to follow the principle of “high-temperature fixation, combining smothering and tossing, less smothering and more tossing, tender fixation for old leaves, and tough fixation for young leaves.” Once the leaves have reached a dark green color, become soft and slightly sticky, and emit a tea aroma, they are immediately removed from the heat. After removal, the leaves should be cooled down quickly, preferably with a fan, to dissipate moisture and lower the temperature, preventing yellowing and waterlogged flavors.

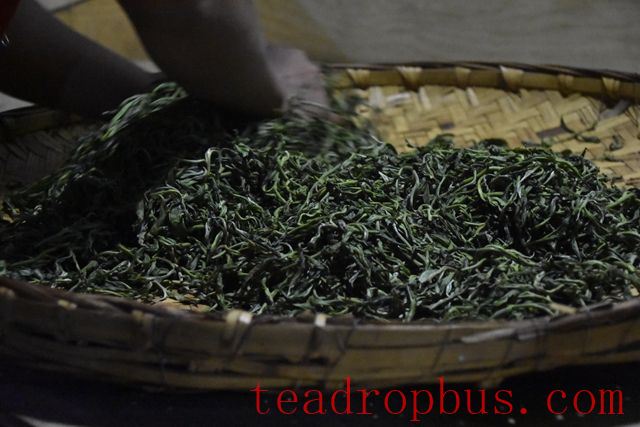

4. Rolling

After fixation, the tea leaves are rolled like dough.

The main functions of rolling include: appropriately breaking down the leaf tissue (the cell damage rate for rolled leaves is usually 45–55%, with tea juice adhering to the surface, giving a slippery and sticky feel when touched), ensuring that the tea juice is easily extracted while also being durable for brewing; reducing the volume to prepare for the final shaping through pan-drying; and shaping the tea into various forms.

Rolling can be divided into hot rolling and cold rolling. Hot rolling refers to rolling the leaves while they are still hot after fixation without any stacking. Cold rolling refers to rolling the leaves after they have been spread out for a period of time, allowing their temperature to drop. Older leaves, which contain higher levels of cellulose, are more difficult to roll into strips and benefit from hot rolling. Higher-grade tender leaves are easier to roll into strips and should be cold rolled to preserve good color and aroma.

Rolling can also be categorized by pressure: light rolling produces strip-shaped tea; medium rolling results in semi-spherical shapes; and heavy rolling creates spherical shapes.

5. Drying

The drying process for green tea typically involves initial oven-drying to reduce the moisture content to a level suitable for pan-drying, followed by final pan-drying. The primary objectives of the drying process are: 1) to continue the chemical changes initiated during fixation, improving the inner quality; 2) to refine the shape based on the rolling, enhancing the appearance; and 3) to remove excess moisture, preventing mold and enabling storage. After drying, the tea must reach a safe storage condition, with a moisture content of 5–6%, such that the leaves crumble when rubbed between the fingers.

Classification of Green Teas

1. Pan-Fired Green Tea

Pan-fired green tea is produced using barrel or pan-firing methods for fixation and drying. Its appearance is tightly bound, with a lustrous green color, a high and fresh aroma, and a clear green infusion, offering a rich yet refreshing taste. Pan-fired green tea has the highest production volume among green teas and can be further subdivided into long pan-fired, round pan-fired, and flat pan-fired varieties. Notable examples include Wuchuan Green, Pingshui Pearl, West Lake Longjing, Biluochun, Liu'an Guapian, Songluo Tea, Xinyang Maojian, and others.

2. Oven-Dried Green Tea

Oven-dried green tea is dried using ovens or dryers. Its appearance is whole, with a deep green and glossy color, a clear and high fragrance, a clear and bright infusion, and a fresh and pure taste. Some notable examples include Huangshan Maofeng, Taiping houkui, Jingtai Green Snow, Tianshan Green Tea, Jiangshan Green Peony, Emei Eyebrow Peak, and Nannuo White Tip.

3. Steamed Green Tea

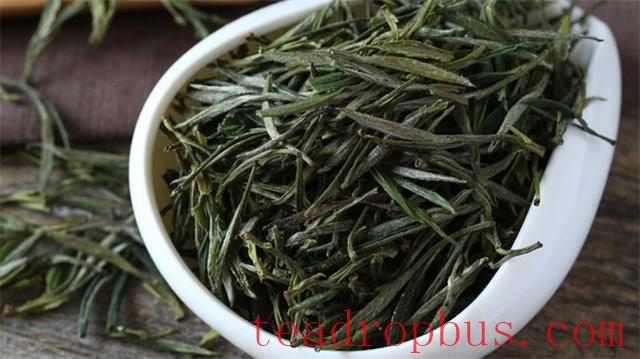

Steamed green tea is one of the earliest methods of producing Chinese green tea, utilizing hot steam for fixation, followed by rolling and drying. Steamed green tea has a tight, needle-like appearance, a fresh or deep green and glossy color, a clear infusion with a light yellow-green hue, a fresh aroma, and a smooth or slightly astringent taste. Currently, the production of steamed green tea in China is relatively small, with major varieties including Enshi Yulu, Chinese Sencha, and some products from Taiwan.

4. Sun-Dried Green Tea

Sun-dried green tea is dried using sunlight. It has a coarse appearance, a deep green and glossy color, a high fragrance, a bright yellow-green infusion, a concentrated and full-bodied taste, and strong astringency. It is primarily produced in Hunan, Hubei, Guangdong, Guangxi, Sichuan, Yunnan, Guizhou, and other provinces, with the best quality coming from large-leaf varieties in Yunnan, known as “Dian Qing.”