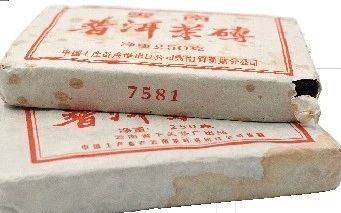

The Mysterious “7581”

The Pu'er brick Tea “7581” has many stories in the Pu'er “world.” Some say this tea is the famous “73 Thick Brick,” some call it the “Cultural Revolution Brick,” and others mention different wrapping papers and varying grades of ingredients… To Chang Jinqiang, the former manager of the Special Tea Department at Yunnan Tea Import and Export Corporation who witnessed its history, “7581” is just an ordinary export tea product.

In 1975, after the artificial fermentation process for Pu'er tea matured, Kunming Tea Factory produced Pu'er brick tea specifically for export, following the convention of using “7581” as the export code for this brick tea.

1975 was a milestone year for Pu'er ripe tea. After Yunnan Tea Import and Export Corporation obtained self-export rights in 1973 and participated in the Canton Fair in Guangzhou, discovering that Pu'er tea sold well in Guangdong and Hong Kong, especially the tea leaves fermented artificially in Guangdong, the company sent several technical personnel from Kunming Tea Factory, Menghai Tea Factory, and Xiaguan Tea Factory to Guangdong to study the rapid artificial maturation technology of Pu'er tea. After returning to Yunnan and practicing at Menghai Tea Factory, they finally mastered the artificial fermentation technique for Pu'er tea in 1975. Kunming Tea Factory began mass-producing ripe tea and used eight-grade Pu'er ripe tea to press into bricks for export, with the export code “7581.”

Ripe Tea for Export; Raw Tea for Domestic Sale

“Before the production of the ‘7581' Pu'er tea bricks in 1975, when the artificial fermentation process for Pu'er tea had stabilized, Yunnan Tea Corporation sent samples to Hong Kong. Only after receiving approval from the primary merchants in Hong Kong did they issue the production plan to Kunming Tea Factory to produce this ripe tea brick. At that time, the most popular products in the Hong Kong market were Pu'er loose tea, followed by cake tea, and lastly brick tea,” Chang Jinqiang explained. The formula for the exported Pu'er brick tea was set in 1975, hence the use of “75.” The third digit “8” represents the comprehensive grade of the tea leaves (a comprehensive grade means that the proportion of eight-grade tea in this brick tea exceeds 50%, so “8” can be used as the ingredient code), while the last digit “1” represents Kunming Tea Factory.

The 7581 brick tea produced by Kunming Tea Factory for export was not the main product of the factory. Kunming Tea Factory also had the important task of producing “border sale” bricks for remote regions within China, as well as Jasmine tea, spring tip Green Tea, and spring bud green tea for the domestic market. The “border sale” bricks were made from unfermented tea leaves. The 7581 brick tea (ripe tea) produced by Kunming Tea Factory had the export code 7581 printed on its outer packaging paper and was exclusively for export. Due to the lower grade of the ingredients used, the price was cheap, and after arriving in Hong Kong, tea merchants would break apart the brick tea and mix it with other loose tea as a “flavor enhancer” to improve taste and color.

Xiaguan Tea Factory and Menghai Tea Factory also produced brick tea, but mainly “border sale” tea, which was sold according to state directives in Tibetan areas and northwest markets. They also produced a certain amount of Pu'er brick tea (ripe tea) for export.

Chang Jinqiang introduced: “The formula for ‘border sale' tea bricks is relatively complex, containing multiple grades of tea and even some broken tea. This is because the lower grade of ingredients results in less Pectin content in the tea, making it difficult to press into shape, and causing significant damage. By adding a certain percentage of broken and sheet tea, the tea bricks become more compact, facilitating pressing and long-distance transportation. If the tea is pressed loosely, it would crumble before reaching its destination, making long-distance transportation very inconvenient. At that time, Kunming Tea Factory, Menghai Tea Factory, and Xiaguan Tea Factory almost never had any broken tea, as all the broken tea was used in border sale tea.”

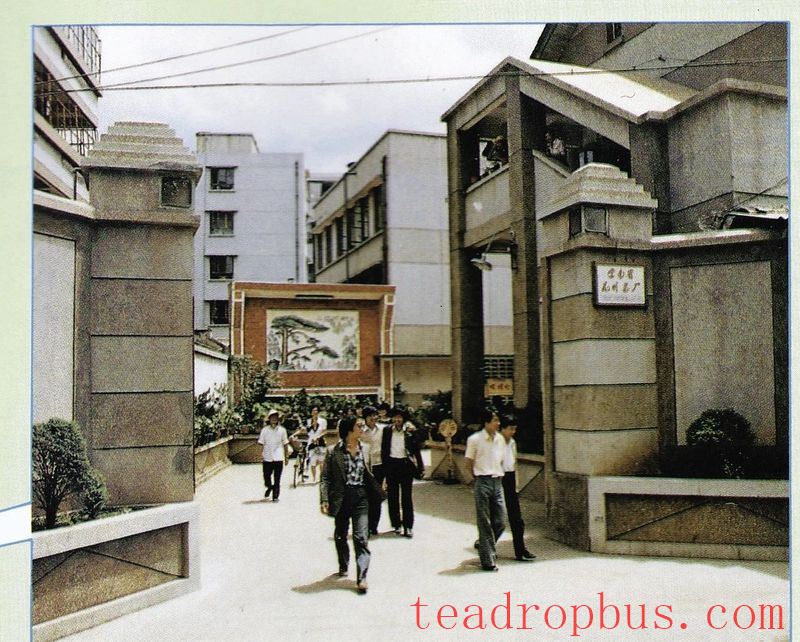

A comparison of the entrance to Kunming Tea Factory in the 1980s (top image) and the 1990s (bottom image).

(Photos provided by Chang Jinqiang)

Decoding the “7581” Through Its Appearance

Chang Jinqiang took out two Pu'er brick teas produced in the same era but from different factories for reference. When placed side by side, there are noticeable differences between the two bricks. Apart from the export codes, the sizes of the 250g tea bricks vary. The 7581 Pu'er brick tea produced by Kunming Tea Factory is flat and elongated, with slightly loosened edges over time. The Pu'er brick tea produced by Xiaguan Tea Factory continues the traditional pressing style of Xiaguan, with a more compact shape and smaller dimensions compared to those produced by Kunming Tea Factory. Despite being over twenty years old, the tea brick remains quite compact.

Due to the limitations of resources and technology at the time, the molds used for making brick tea were heavy cast-iron molds. These molds consisted of three parts: a metal frame, a top cover, and a bottom plate. The rectangular cast-iron frame had two handles on either side, and the bottom plate had several rows of irregular air holes. After pouring the tea leaves into the frame, steam would rise through the air holes, softening the tea leaves and making them pliable. Then, the top cover would press the tea leaves tightly and push them into the press machine. After removing the mold, the bottom plate would be taken out, and the formed tea brick would be extracted. It's clear that pressing tea bricks was a physically demanding task. Many protruding air holes could be seen on the back of Pu'er brick tea, commonly known in the industry as “milk nipples,” which were a legacy of traditional brick tea manufacturing techniques at that time. Unexpectedly, these “milk nipples” have become one of the pieces of evidence for identifying the production era and authenticity of brick tea today.

With the accumulation of production experience and technological advancements, improvements were made to the original production methods. In the early days, the direct exposure of the air holes and the bottom surface of the tea bricks to steam resulted in blackening due to excessive moisture. To address this, a piece of undyed “raw white cloth” was placed in the mold's groove. This prevented the blackening of the air holes and the bottom surface of the tea leaves, and also made the tea bricks easier to remove from the mold, achieving two goals at once. With the addition of the white cloth, the pressed tea bricks showed clear fabric patterns and the shapes of the “milk nipples.”

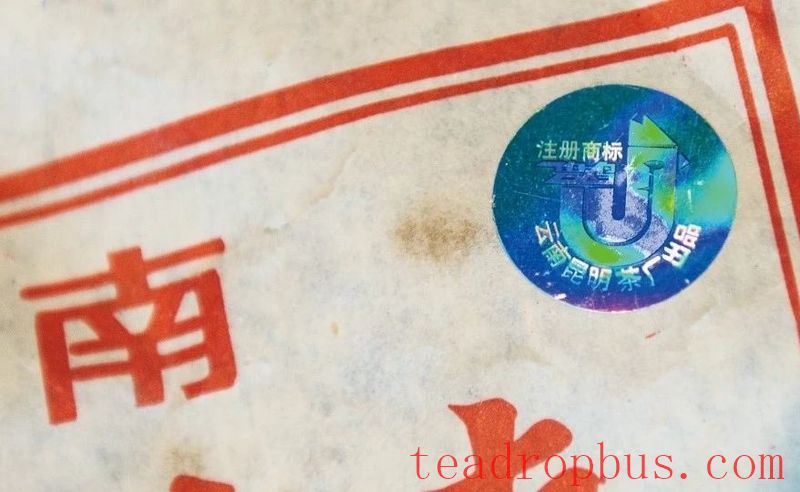

Pu'er brick tea produced by Kunming Tea Factory in 1993, with holographic labels added.

(Photo: Duan Zhaoshun)

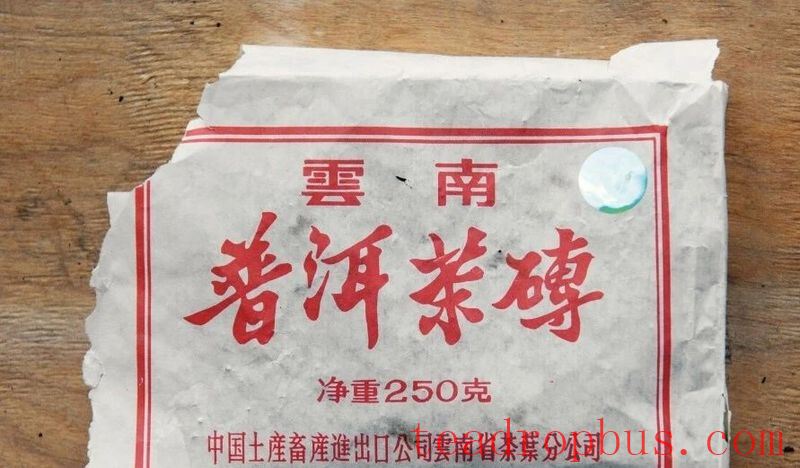

Pure Coincidence of Outer Packaging

The regular packaging for the 7581 brick tea produced by Kunming Tea Factory featured red text on white paper, with the export code 7581 printed on the outer packaging paper. Some overseas customers wanted their tea to stand out and requested Chang Jinqiang to make changes to the packaging paper of the ordered brick tea, resulting in the appearance of 7581 brick tea packaged in chicken skin paper with slightly smaller font size. Additionally, a small amount of brick tea with green text on white paper was produced. “Apart from the difference in the packaging paper