In recent years, the group of consumers drinking aged Tietguanyin Tea with coniferous aroma has been expanding. Some tea producers and leading Oolong tea enterprises produce aged Tietguanyin, and many tea companies also accumulate a considerable amount of aged tea in stock year by year. However, there are problems such as unscientific processing methods causing the aged Tietguanyin to taste sour or develop a burnt charcoal flavor, and improper storage conditions leading to off-flavors or even mold, which seriously affect the income of tea farmers and the economic benefits of enterprises.

The article introduces a set of far-infrared Roasting method and cellar storage method suitable for aged Tietguanyin with coniferous aroma. It explores key technologies for optimizing the roasting and storage of aged Tietguanyin tea, improving the quality of aged Tietguanyin, addressing the pressing issues faced by tea companies and tea farmers, and enhancing the market value and brand effect of aged Tietguanyin.

01

Design of Fully Automated Far-Infrared Drying Machine

Roasting is one of the critical steps in processing aged Tietguanyin with coniferous aroma. Temperature and time are two major factors that determine the quality of roasting. Through long-term production practice, it was found that traditional charcoal roasting results in more mature and thorough roasted tea compared to electric oven roasting, with a smoother taste. The reason is that in addition to generating heat, charcoal roasting also emits far-infrared rays from the glowing charcoal, which have strong penetrability, heating the tea granules simultaneously from the outside to the inside, allowing them to ripen synchronously.

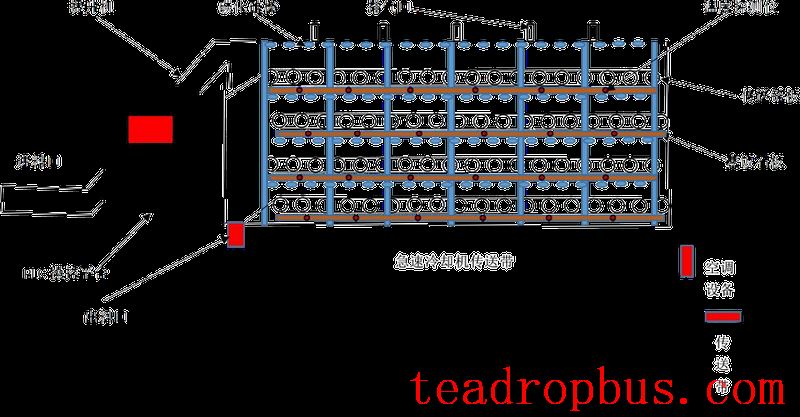

Based on this physical phenomenon, the research team designed and assembled a fully automated far-infrared drying machine relying on the utility model patent “A Device for Maturing and Enhancing Aroma of Tea” (Patent No.: ZL 2012.2.0096910.0). The total length of the machine is 12 meters, with four layers of movable chain plates inside. The total length of the chain plates is 48 meters, and each layer is equipped with 22 silicon carbide rods (24 on the third layer), each rod carrying 1 kW of load. After electrification, the silicon carbide rods not only emit heat but also far-infrared rays with wavelengths between 4 and 14 μm, characterized by their beam-like nature and strong penetrability. This wavelength range has a high heat output and temperature, along with strong penetration, enabling objects being heated to gain a significant amount of energy within a short period.

▲ Schematic Diagram of Far-Infrared Drying Machine

The bottom plate is covered with mazusite, a natural silicate mineral. Firstly, mazusite is porous, with strong adsorption capacity, capable of absorbing off-flavors and impurities from aged Tietguanyin tea with coniferous aroma. Secondly, mazusite contains zirconia, which emits far-infrared rays, further heating the tea and improving efficiency. Thirdly, due to its rough surface and porosity, mazusite can scatter the far-infrared rays emitted by the silicon carbide rods, providing all-around heating to the tea.

Programmable Logic Controller (PLC) control technology is also applied, strengthening the human-machine interface and software design. By controlling the power supply to different silicon carbide rods, the temperature and intensity of the far-infrared rays, as well as the speed of each layer of the chain plate, can be adjusted. The speed of the chain plates can be controlled within 0 to 120 cm/min, thereby mastering the roasting time of the far-infrared drying machine to achieve the purpose of controlling the degree of roasting.

The process flow for fully automated far-infrared roasting of aged Tietguanyin with coniferous aroma is as follows:

Feeder → Stem Picker → Color Sorter → Sifter → Air Separator → Visual Selector → Electrostatic Stem Picker → Storage Bin → Elevator → Far-Infrared Drying Machine → Rapid Cooling Machine → Blending → Packaging.

Different specifications and models of elevators link various machinery components to avoid the tea touching the ground and prevent secondary contamination.

02

Construction of Cellar for Storing Aged Tietguanyin Tea with Coniferous Aroma

1. Cellar Design

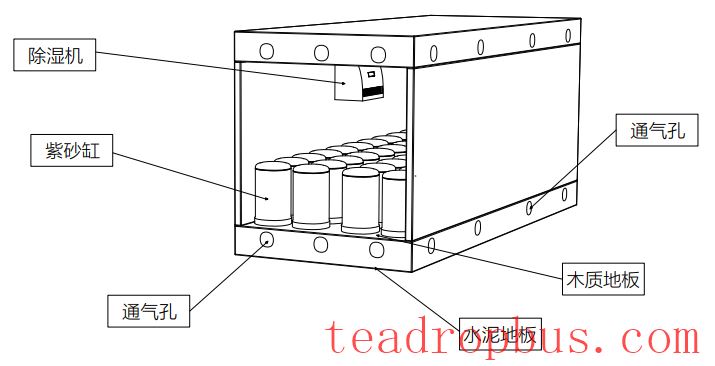

Select a room facing north and south, with walls no less than 4 meters high. Windows should be opened on the east, south, west, and north sides as much as possible and curtains installed to prevent direct sunlight. Natural fir wood panels are used to seal off the room above, below, front, back, left, and right, leaving a 10 cm gap between the front and back, and left and right walls, and a 40 cm gap between the top and ceiling. At a distance of 10 cm from the ground and the ceiling, several ventilation holes measuring 30 cm (high) × 40 cm (wide) are opened as louvered windows. The six surfaces of the tea cellar should maintain a certain distance from the walls of the storage room, which facilitates ventilation. As the temperature and humidity change through the seasons, it promotes the post-ripening of the tea stored in the cellar.

▲ Actual Picture of the Tea Cellar

2. Key Points for Storage

Construct a relatively sealed wooden storage warehouse according to the company's storage capacity. If there is high-quality aged Tietguanyin, it can be stored in large purple clay jars. First, line the purple clay jar with a layer of Xuan paper. Place the high-quality aged Tietguanyin with coniferous aroma inside the purple clay jar lined with Xuan paper, wrap the tea with Xuan paper, cover it, and place the purple clay jar on a wooden floor. Install a dehumidifier in the storage room. During seasons with heavy rainfall, use the dehumidifier to maintain a low-humidity environment. This wooden tea cellar avoids direct sunlight and maintains the optimal storage environment of natural ventilation.

▲ Second Level of the Tea Cellar – Purple Clay Jars

The construction mode of the tea cellar provides three layers of isolation protection for aged Tietguanyin with coniferous aroma: the first layer is the wooden wall isolating moisture in the air and off-flavors from cement brick walls; the second layer is the purple clay jars, which change with seasonal temperatures, promoting the post-ripening of the tea and isolating moisture and off-flavors in the cellar space; the third layer is Xuan paper, which is both hygienic and absorbs moisture between the tea particles. This tea cellar design received a utility model patent (Patent No.: ZL2025.2.0678920.X), as shown in the figure.

Place aged Tietguanyin with coniferous aroma into purple clay jars lined with Xuan paper and orderly arrange the jars inside the wooden tea cellar. This structure of the tea warehouse has the effect of keeping warm in winter and cool in summer. After roasting and cooling to room temperature, the aged Tietguanyin is sealed and stored in the tea cellar, remaining cool during hot summers and warm during cold winters. Through the post-ripening and a series of changes in internal components, the tea soup of aged Tietguanyin acquires characteristics of “smoothness, slipperiness, clarity, and freshness,” reflecting the style of coniferous aroma, sweet and mellow.

03

Quality Comparison of Aged Tietguanyin with Different Roasting Methods

1. Experimental