“The world's black Tea originates from Wuyi.” Zhengshan XiaoZhong is the oldest Black Tea in existence today and is considered the ancestor of all black teas worldwide. The British referred to Zhengshan XiaoZhong as Bohea Tea since 1692, and by 1878 when it was exported from Fuzhou, it was also known as Lapsang souchong. Originating from Tongmu Pass in Xingcun Town, Wuyi City, Fujian Province, Zhengshan XiaoZhong has a history of over 400 years and carries significant cultural and historical weight. In this article, we will explore the manufacturing techniques of Zhengshan XiaoZhong.

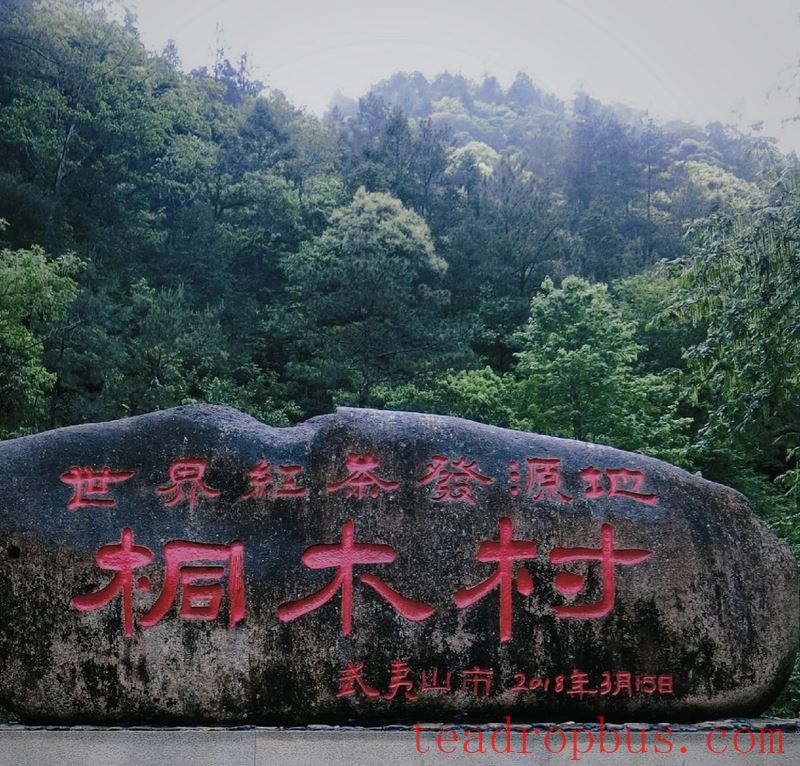

Tongmu Pass, the Birthplace of Zhengshan XiaoZhong

The manufacturing process of Zhengshan XiaoZhong is divided into: primary processing and finishing processing.

PART01 Primary Processing

Harvesting (fresh leaves) — Withering — Kneading — Fermentation — Red Pan — Re-kneading — Smoking — Drying — Raw Tea.

01 Harvesting (Fresh Leaves)

The fresh leaves for Zhengshan XiaoZhong are typically harvested in early May, usually one bud with three leaves. Each batch should have consistent tenderness, uniformity, purity, and freshness.

02 Withering

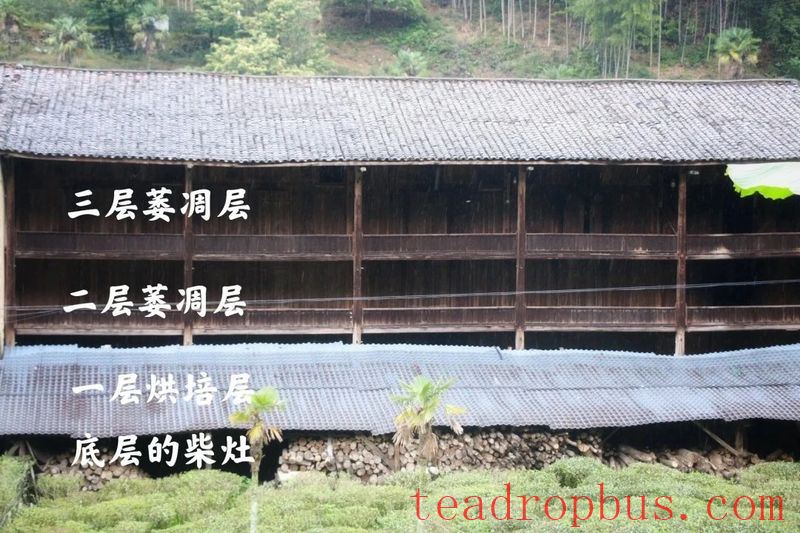

There are two methods for withering Zhengshan XiaoZhong: sunlight withering and heat withering. As there is more rain than sunshine during the tea-making season in Tongmu Pass, indoor heat withering is commonly used. Heat withering takes place in the “Green Building,” which has three floors. The second and third floors have crossbars with bamboo mats laid on top where the fresh leaves are spread out. The bottom floor is used for smoking the re-kneaded tea, connected through a smoke duct to a firewood stove outside. When pine wood is burned, the heat enters the bottom floor, drying the tea while using the residual heat to warm the fresh leaves on the upper floors. Sunlight withering is performed outdoors on sunny days, by spreading the fresh leaves evenly on bamboo mats under the sun.

The Green Building

03 Kneading

After adequate withering, the fresh leaves can be kneaded. In earlier times, this was done manually until the tea leaves were tightly rolled and tea juice oozed out. Nowadays, a tea kneading machine is used instead.

04 Fermentation

Zhengshan XiaoZhong uses hot fermentation, placing the moderately kneaded tea in a bamboo basket and covering it with cloth or thick fabric. The tea ferments due to its own enzymes, and after a certain period, when the tea turns reddish-brown and emits a fresh scent, it can be taken out for the red pan step.

05 Red Pan

This is a unique step in the manufacturing of Zhengshan XiaoZhong. The purpose of the red pan is to halt enzymatic activity and stop fermentation, preserving the sweet and pure aroma and flavor of the tea. This involves tossing the fermented leaves into a heated iron pan and stirring them with both hands. This technique requires strict control, as too long a time can result in excessive moisture loss and burnt leaves, while too short a time does not enhance the aroma and flavor sufficiently.

06 Re-kneading

The tea after the red pan must be re-kneaded to tighten the loosened tea leaves. The method involves immediately placing the tea into the tea kneading machine while it is still hot, and continuing until the tea leaves are tightly bound.

07 Smoking

The re-kneaded tea is spread out on bamboo trays and placed on racks in the bottom floor of the “Green Building.” Pine wood is burned in an outdoor stove, and the hot air is directed into the building's bottom floor. During the drying process, the tea continuously absorbs the fragrance of the pine, imparting Zhengshan XiaoZhong its distinctive pine resin aroma.

08 Drying

After sieving and removing coarse leaves and old stems, the dried tea is placed on bamboo trays and smoked again with pine wood to enhance the unique aroma of Zhengshan XiaoZhong. After these steps, the tea becomes the raw product of Zhengshan XiaoZhong.

PART02 Finishing Processing

Grading and Batching — Raw Tea Piling — Water Reduction Drying — Sieving — Air Selection — Sorting — Drying — Blending — Packing (Finished Product).

01 Grading and Batching

When raw tea arrives at the factory, it is sorted and stored according to grade to facilitate blending based on origin, season, appearance, and quality standards from previous years.

02 Raw Tea Piling

The graded and batched raw tea is piled according to the blending ratio to ensure consistency in the final product.

03 Water Reduction Drying

During the piling process, the moisture content of different batches of tea may vary, some may become damp, or have high moisture content, requiring additional drying to achieve uniform moisture levels for processing.

04 Sieving

The tea is sieved to sort the appearance, remove stems, and retain leaves that meet the grading criteria for appearance and purity. Sieving methods include: flat circular sieves, shaking sieves, cutting, lifting sieves, floating sieves, and air selection. The processing can be divided into five categories: whole, round, light, broken, and fragmentary.

05 Air Selection

The tea after sieving is further processed through fans, using air to separate fragments, leaving only the tea within the grade.

06 Sorting

Tea stems, non-conforming shapes, and non-tea materials that remain after air selection are removed, ensuring uniform appearance and meeting purity requirements for the grade. Sorting can be done mechanically or manually. Mechanical sorting is typically used first to reduce manual labor, followed by manual sorting to guarantee the required purity and color, ensuring the safety and hygiene of the tea quality.

07 Drying

After sieving and air selection, the black tea may absorb moisture, leading to high moisture content, so additional drying is required to meet the moisture content requirements. For the finished smoked Zhengshan XiaoZhong, a stronger and longer-lasting pine aroma (longan dried fruit aroma) is desired, so an additional pine smoking step is added during the final drying process to allow the dry tea to absorb the fragrance. After smoking, Zhengshan XiaoZhong has a strong and rich pine aroma (longan dried fruit taste) and a glossy black appearance.