Pure and high-quality clay from the original mine often displays various flaws during firing, but this is not always the case.

A Teapot that exhibits characteristic flaws of high-quality original mine clay must meet one or more of the following conditions:

Cracks on the bottom of the pot (appearing after the first firing)

One: “The clay must be from the original mine and have a certain degree of sandy texture.”

Two: “The purity of the clay and the raw material selected must be sufficiently high.”

Three: “The clay must consist purely of sand particles or contain an absolute minimum of fatty clay.”

Why are many Teapots in the market cheap yet perfect?

The reason why there are a large number of machine-made and hand-pulled teapots on the market has to do with most novice teapot enthusiasts. Nobody wants to accept flaws, believing that since they spent money, they should get a flawless product. Some people don't even consider authenticity and quality; many novice enthusiasts think a teapot looks good, so it must be well-crafted. This is a big mistake. There are many machine-made zisha teapots, seemingly flawless and attractively priced, for just tens or a hundred yuan, sometimes including six cups, readily available on Taobao. Ultimately, this is due to a lack of understanding about zisha!

What kind of flaws do high-quality original mine clays typically display?

Bubbles (common in original mine clay, a normal phenomenon)

“Bubbles, popping, and mud bursts”:

Clay that exhibits these phenomena is usually pure sand particles or has a very high sand content. During firing in the kiln, the entire pot contracts, and some slightly larger particles may crack due to rapid temperature changes, causing them to pop out without any buffer around them. The occurrence of these flaws can be reduced by controlling the speed of temperature changes in the kiln, but most people do not have their own kilns, and those who do may not know how to control the firing process. Therefore, preventing such issues remains a challenge.

The fundamental cause of this situation is low plasticity, insufficient compaction when crafting (the hardwork of the pinching tool is not hard enough), uneven force when opening, etc. Even top experts find it difficult to avoid flaws with this kind of clay.

Mottling (can be removed if conditions allow)

“Mottling”:

The main reason is the hardness of the sand particles and the purity of the clay. When attaching the handle and spout, the density of the fatty clay used may differ from that of the body, or the finishing work may be inadequate, or the pot body is not moistened when using the pinching tool, which can cause the sand particles to fray. Or, the finished clay may have been stored for too long, causing different humidity levels inside and outside the zisha clay. Therefore, before making a teapot with long-stored finished clay, it's best to rework it or repeatedly hammer it. Typically, mottling is very slight before the pot reaches its crystallization point during firing. In most cases, mottling appears after crystallization. Therefore, do not reject pots with mottling; they are genuine zisha teapots. Although not very attractive, some mottling can be eliminated through use.

“Gray bursting”:

This occurs when limestone particles mix into pure zisha clay and turn into lime at high temperatures, expanding and bursting due to the very small buffering capacity of pure sand materials, forming gray bursts.

The fundamental cause of surface cracks or fractures is the pure sandiness, as the saying goes, the clay is explosive, with very low viscosity. Many pure and hard sand materials exhibit cracks or fissures on the surface, most of which can only be seen with a magnifying glass, but do not leak. This situation is very normal.

Mud Burst (if the area is too large, it affects use and appearance, considered a flaw)

“Bubbles, mud burst”:

Clay that exhibits this situation generally has good purity, high hardness, and slightly larger particles, usually appearing in hard sand clays between 40 and 60 mesh. The main reason is the firing method and atmosphere in the kiln. If the temperature changes too quickly in the kiln, larger particles may crack due to significant thermal stress differences, resulting in bubbles or popping. Some clays, although fine, may also exhibit this due to the slightly inferior quality of the raw material itself when the kiln temperature increases too rapidly or exceeds the clay's firing temperature.

Sand popping (very slight, does not affect use, unclear without a magnifying glass)

“Sand popping”:

The cause of sand popping is simple: during firing, the pot body contracts, and the sand particles have no buffer between them, causing the sand particle with the least adhesive strength to pop out under pressure. From this perspective, teapots with sand popping are mostly made of pure and high-quality hard sand materials. To eliminate sand popping, simply add more fatty clay to the clay, but while the popping stops, the quality of the clay also decreases.

Iron black (if the area is too large, it cannot be used, considered a flaw)

Iron melting points (too small to notice without careful examination, not within the range of flaws)

“Iron black, iron melting”:

Iron black refers to iron that melts beneath the surface of the pot but has not yet emerged. Iron melting refers to crystallized iron that has melted and emerged on the surface.

Pure and high-quality clay from the original mine often exhibits iron black and iron melting at a certain temperature during firing. Iron black is relatively common in zisha clay, and the quality of the clay is generally not poor. Only original mine clays can exhibit iron melting, and they must meet the following two conditions: First, the clay must be pure sand particles after sieving, or the fatty clay content must be extremely low. Second, regardless of whether the clay is soft or hard, it must be fired to near crystallization, meaning the clay must be transformed into a zisha teapot. From these two points, a teapot with iron melting points is undoubtedly made of high-quality clay. There is currently no scientific explanation for the formation of iron black and iron melting, but it may be related to the purity of the original mine clay. Conversely, even the best original mine clay will not exhibit iron melting if it is not sufficiently pure.

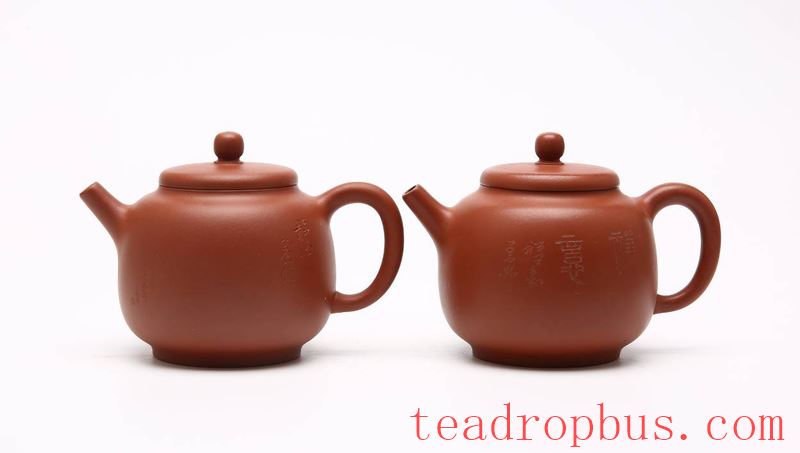

Comparison of a zisha teapot made from original mine clay before and after patination

The teapot after patination, upon close inspection, also shows common minerals and black spots found in zisha

Most of these phenomena occur only in high-quality original mine clays. People with a high level of understanding of zisha generally do not refuse the normal flaws that appear in high-quality clays. Those with lower understanding cannot tolerate any flaws.

Many people mistakenly believe that spots on zisha teapots are flaws, but both black iron ion spots and shiny mica spots are quality indicators of zisha clay.

If there are copyright issues, please contact us to remove the content.