White Tea is one of the six major types of tea in China, with a smaller output but significant potential for growth. According to statistics from the Chinese Tea Circulation Association, the total production of tea in China reached 2.986 million tons in 2025, with White Tea accounting for 2.47% of this total, representing a significant increase of 56.3% compared to 2025. In 2025, the agricultural value of white tea nationwide was approximately 7.52 billion yuan, an increase of 20.1 billion yuan over 2025, marking a growth rate of 36.41%. The significant growth in both output and value indicates the rapid development of the white tea industry.

Traditional white Tea processing involves withering and drying without pan-frying or kneading, resulting in loose and light tea leaves that have poor flowability during refining and are difficult to process continuously and automatically. Currently, there is a lack of mature, complete sets of refining equipment on the market; instead, manual sorting, stacking and blending, or semi-mechanical, semi-automated production methods are primarily used. These methods often result in high breakage rates, significant losses, uneven blending, and excessive foreign matter content.

In recent years, relevant departments in Fujian Province have actively promoted the concept of “innovating processes to improve mechanization and standardization levels to drive the development of the white tea industry.” As a white tea company with a 71-year history, Fujian Tea Import and Export Corporation has actively implemented the concept of high-quality development in white tea. Since 2025, it has relied on professional technology to conduct research and development of white tea refining processing technologies and integrated the application of complete sets of production line equipment. In 2025, an automated and sanitary white tea refining production line was integrated and has been in continuous use for four years. This not only ensures product quality and hygiene but also significantly reduces employee workload, increases output efficiency and economic benefits, effectively promoting the high-quality development of white tea.

01

Key Points and Challenges of the Production Line Technology

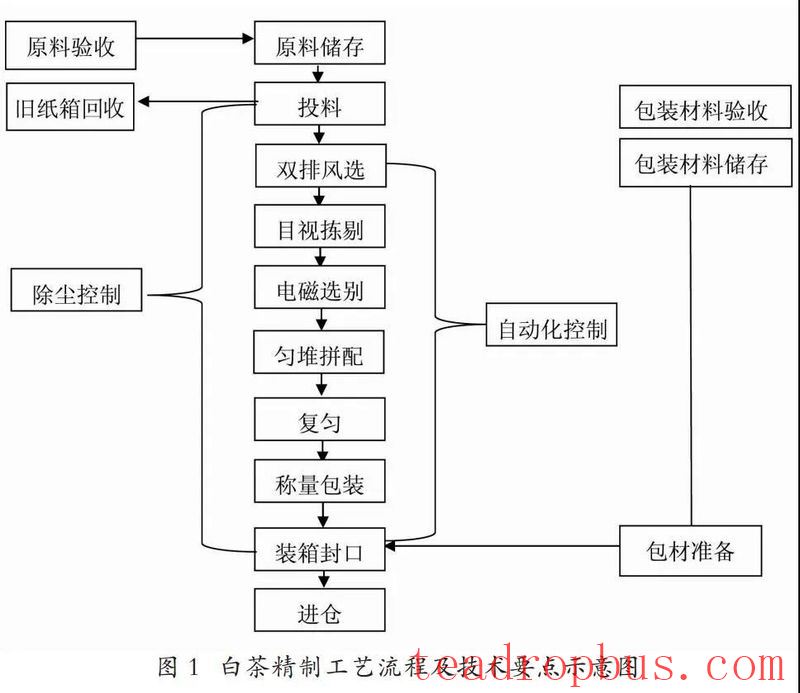

White tea raw materials or semi-finished products generally need to undergo sorting out foreign matter, blending, packaging, and other processes before they can be sold as finished tea. Therefore, the white tea refining production line is designed with wind selection, electrostatic selection, visual sorting, magnetic selection, blending, weighing and packaging, boxing, and other steps.

The design of the production line addresses five common technical challenges encountered during the refining of white tea. Firstly, it solves the issue of poor flowability due to the large and light nature of white tea leaves, which can easily cause blockages during processing. Secondly, it improves and applies the “cabinet-style horizontal laying and vertical cutting” blending technology to minimize the breakage and loss rates of white tea and solve the sanitation issues during blending, improving the uniformity of the tea blend. Thirdly, it addresses the problem of difficulty in removing grass hairs and other foreign matter from white tea raw materials, improving the hygiene level of the final product. Fourthly, it employs computer monitoring systems and automation control technologies to enhance the efficiency and automation level of white tea refining. Lastly, it improves dust and noise control technologies, enhancing the cleanliness of white tea refining and achieving energy-saving and environmental protection goals. Key technological points of the white tea refining process and production line are shown in Figure 1.

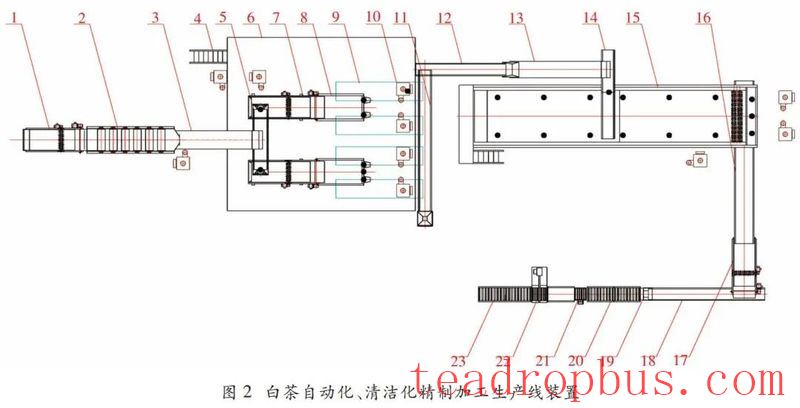

The design of the production line is shown in Figure 2. It is equipped with two dual-row wind separators, one multifunctional wind separator and one electrostatic separator each for head and tail teas, four visual sorting machines, four magnetic drums at 3000 Gauss, one strong magnet bar at 9000 Gauss, one automatic blending machine with a capacity of 60 cubic meters, one set of vibrating boxing machines, one automatic packing machine, and ten filtered cylinder dust collectors. The entire production line has a capacity of 400 kg per hour and an annual capacity of 700 tons of refined white tea.

1. Solving the Flowability Problem in Continuous Refining Processing of White Tea

Due to the loose and light nature of white tea, the leaves tend to tangle and stick together, leading to bridging and blockages during material handling, feeding, and stacking. To address these issues, the production line has been specifically designed with improvements such as:

a) Widened and heightened custom feeders and elevators are used in all feeding and conveying stages. b) A tea conveyor and tea boxing vibrator that are easy to disassemble and automatically scrape out tea dust have been developed. c) An expanded dual-row wind separator is innovatively applied. d) The blending machine's base is raised to increase the drop distance of the white tea. These optimization measures are concentrated in the devices for sorting and blending white tea, ensuring smooth processing without obstructions.

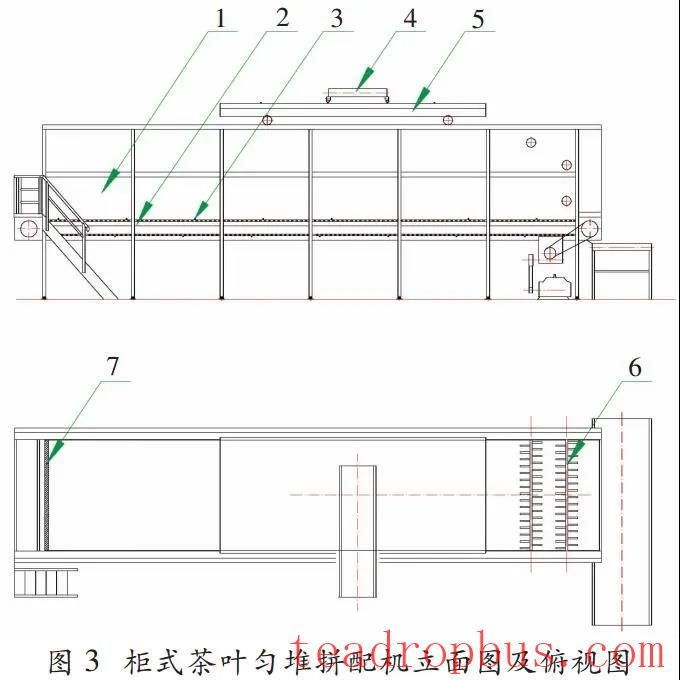

2. Upgrading the “Cabinet-style Horizontal Laying and Vertical Cutting” Blending Technology

Currently, most blending of white tea is done manually on Ceramic or metal troughs in China, which results in significant labor requirements and uneven blending. Manual stomping during blending and stacking can also lead to higher breakage and loss rates, along with product hygiene issues due to human contact and dust. The production line utilizes the advantages of the cabinet-type blending machine to improve the “cabinet-style blending” technology by adopting the “cabinet-style horizontal laying and vertical cutting” method. An auxiliary rake and pusher are designed to facilitate the flow of tea. The mechanical rake hand can vertically move the white tea during stacking, mixing the different grades of tea from top to bottom to improve blending uniformity. A schematic diagram of the cabinet-type blending machine structure is shown in Figure 3.

Furthermore, the computer can automatically control the travel and step size of the blending machine, achieving an even distribution of different grades of tea. This technology can reduce the breakage and loss rates during white tea refining and improve product cleanliness.

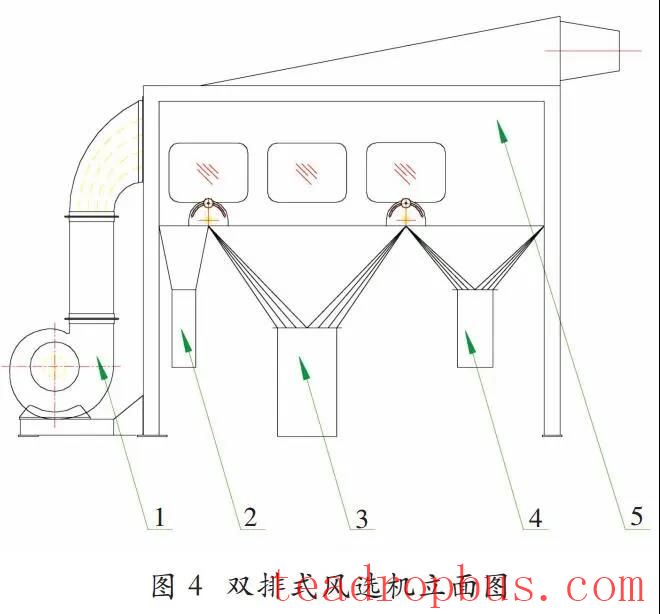

3. Addressing the Challenge of Removing Foreign Matter from White Tea Raw Materials

Foreign matter such as grass hairs and sandstones in white tea raw materials is difficult to remove even with manual visual sorting. The production line is based on strip tea processing wind selection equipment and has designed and improved a dual-row wind separator for white tea selection, as shown in Figure 4. The wind separator effectively removes various types of sandstones and grass hairs, significantly enhancing the hygiene level of white tea products. The dual-row wind separator is an upgraded version of the single-channel wind separator, widened and equipped with dual rows of blowers. It has three outlets: sandstone outlet, clean tea outlet, and grass hair outlet. The sandstone outlet contains a mixture of sandstones and tea (head tea); the clean tea outlet contains selected clean tea; and the grass hair outlet contains a mixture of grass hairs and tea (tail tea). After processing by the dual-row wind separator, the sandstone-containing head tea and grass hair-containing tail tea are further processed through a multifunctional wind separator and an electrostatic separator to effectively recover tea, reducing loss.

4. Integration of Automation Control Technology in the Tea Production Line

Selecting equipment according to the basic requirements of the white tea refining production line, important refining steps such as sifting and wind selection, electrostatic selection, visual sorting, electromagnetic selection, blending, and boxing are configured. Automatic weighing, automatic boxing, automatic packing, automatic detection, alarm protection, video surveillance, and other automation control technologies are integrated, greatly increasing the production efficiency of the tea production line. The automation control interface of the production line is shown in Figure 5. The number of operators has been reduced from 24 to 12, effectively improving the high degree of dependence on manual labor in the white tea industry and significantly enhancing automation levels.