Fuding white Tea is produced in Fuding City, Fujian Province, with a long history and excellent quality. It can be categorized into Bai Hao Yin Zhen (Silver Needle), Bai Mudan (White Peony), Gong Mei (Tribute Eyebrow), and Shou Mei (Longevity Eyebrow). Apart from differences in raw materials, the production processes for these four types of Fuding white teas are similar and can generally be divided into withering and drying. The drying process is used to remove excess water from the leaves after withering and to deactivate enzymes such as polyphenol oxidase, improving the aroma and taste of the finished product. Drying is a critical step in forming the quality of White Tea, affecting both its appearance and internal properties.

The commonly used drying methods for Fuding white tea are charcoal baking and electric baking. Charcoal baking is more traditional, using ignited charcoal as the heat source. Some researchers believe that charcoal-baked tea has certain advantages in terms of quality and storage. Electric baking is the most commonly used drying method in the production of various teas, utilizing electrically heated air. Compared to charcoal baking, electric baking offers better control over temperature and heating time, resulting in more consistent tea quality.

Given the importance of the drying process for the quality of white tea, selecting an appropriate drying method is significant for the formation and control of white tea quality. This study compares the internal substances and aroma components of Fuding white tea processed by different drying methods to explore their effects on the quality of white tea, aiming to provide some production guidance for Fuding white tea.

Materials and Methods

1. Materials and Reagents

In September 2025, the one bud and two or three leaves of the Fuding Dahai tea variety were picked. After withering, they were dried using the following methods:

· Electric Baking Group (DB): 75°C electric baking for 120 minutes

· Low-Temperature Charcoal Baking Group (TB-L): 55-65°C charcoal baking for 120 minutes

· High-Temperature Charcoal Baking Group (TB-H): 70°C charcoal baking for 120 minutes

Results and Analysis

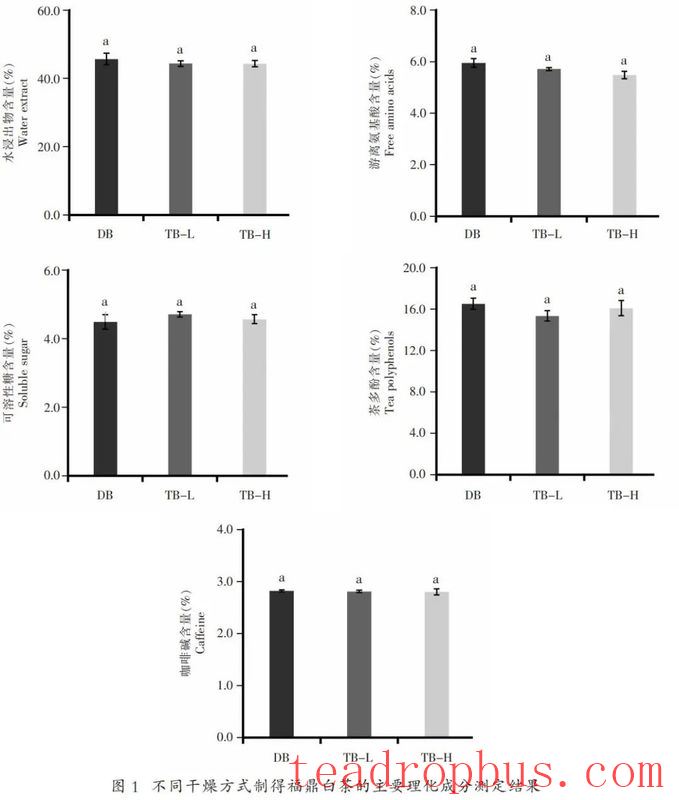

1. Changes in Physicochemical Components

The results of the determination of water-soluble extracts, free amino acids, tea polyphenols, soluble sugars, and caffeine in the three types of tea samples processed by different drying methods are shown in Figure 1. The results show that there are no significant differences in the contents of free amino acids, tea polyphenols, soluble sugars, and caffeine in the Fuding white tea samples processed by different drying methods.

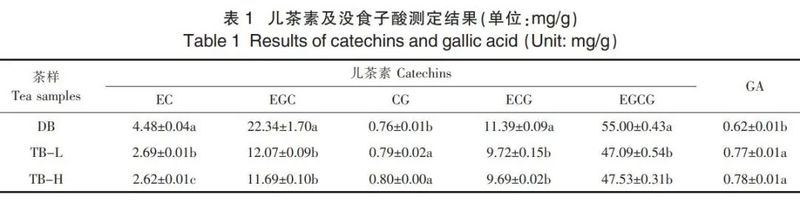

2. Changes in Catechin Composition

The HPLC determination results are shown in Table 1 and Figure 2. The contents of EC, EGC, ECG, and EGCG in the electric-baked white tea are significantly higher than those in the charcoal-baked group, with considerable differences. The contents of CG and GA are lower in the electric-baked group, but since these two monomers have low content in tea, their differences do not significantly impact the overall quality of the tea. It was also found that the contents of ester-type catechins, non-ester-type catechins, and total catechins in the electric-baked white tea are significantly higher compared to the charcoal-baked group. These experimental results indicate that electric baking better preserves the catechins in Fuding white tea compared to charcoal baking. There were no significant differences in the contents of individual catechins and total catechins between the low-temperature charcoal baking group and the high-temperature charcoal baking group, suggesting that changes in drying temperature within a certain range do not affect the catechin content in the finished tea.

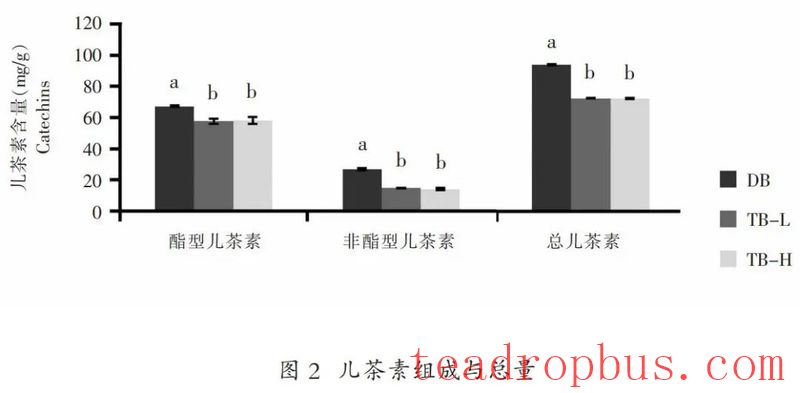

3. Changes in Aroma Components

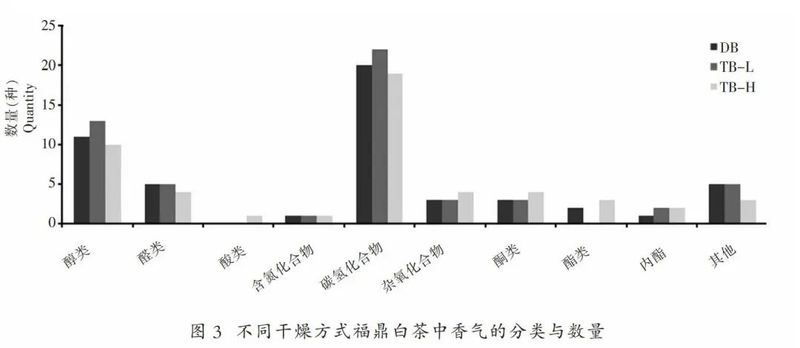

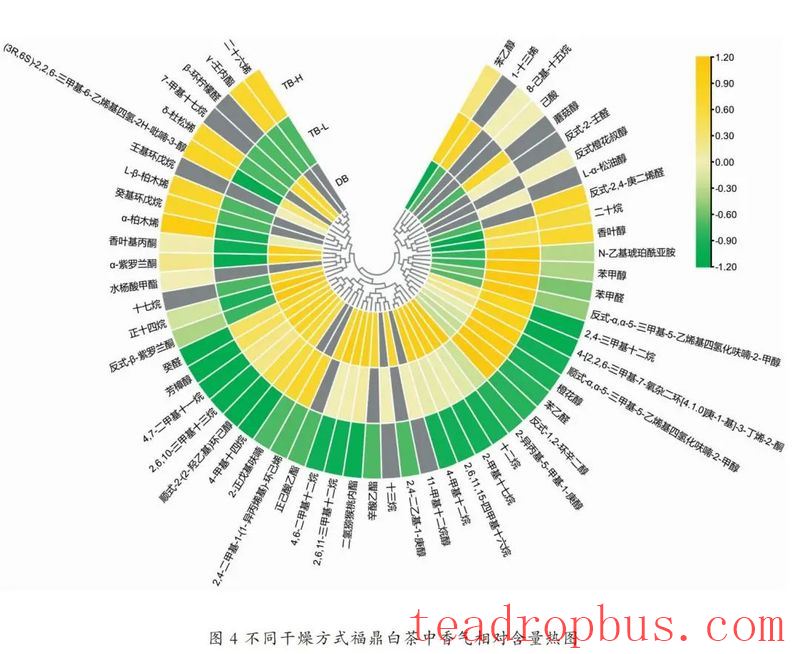

The results of the aroma analysis of Fuding white tea processed by different drying methods are shown in Figures 3 and 4. A total of 51, 54, and 54 types of aromas were detected in the electric baking group, low-temperature charcoal baking group, and high-temperature charcoal baking group, respectively. Observing Figure 3 reveals that there are no significant differences in the types and quantities of aromas among the different tea samples.

Figure 4 shows that the aroma components with relatively low content in the electric baking group and high content in the charcoal baking group mainly include eicosane, geraniol, and phenethyl alcohol. Eicosane is typically present in roasted tobacco leaves, and it is speculated that its formation may be related to charcoal baking. Geraniol and phenethyl alcohol have a rose-like aroma. The aroma components with relatively low content in the charcoal baking group and high content in the electric baking group mainly include β-ionone, β-cyclocitral, geranyl acetone, and some alkanes, which help the electric-baked tea exhibit a better fresh floral aroma.

It is noteworthy that there are significant differences in the relative contents of multiple aroma components between the low-temperature charcoal baking group and the high-temperature charcoal baking group. α-Cedrene, (3R,6S)-2,2,6-trimethyl-6-vinyltetrahydro-2H-pyran-3-ol (fruity fragrance), and δ-cadinene (woody odor) have lower contents in the low-temperature charcoal baking group and higher contents in the high-temperature charcoal baking group. Benzaldehyde (sweet fragrance), nerol (fruity fragrance), linalool, α,α-5-trimethyl-5-vinyltetrahydrofuran-2-methanol (linalool oxide), 4-[2,2,6-trimethyl-7-oxabicyclo[4.1.0]hept-1-yl]-3-butene-2-one, 2,4-dimethyl-1-(1-isopropenyl)cyclohexene, and dihydroactinidiolide (coumarin, musk-like odors) have higher contents in the low-temperature charcoal baking group and lower contents in the high-temperature charcoal baking group. These results suggest that the tea processed by high-temperature charcoal baking has a higher degree of fire processing and a lighter fruity fragrance compared to the low-temperature charcoal baking group. They also indicate that drying temperature is one of the key factors influencing the formation of aroma in the finished tea.

4. Changes in Sensory Evaluation

The sensory evaluation results are shown in Table 2. The sample from the electric baking group scored the highest at 89.90 points, with its dry tea appearance having a slightly superior color compared to the charcoal baking group. There were no significant differences in the color of the tea infusions among the three groups. In terms of aroma, the tea sample from the electric baking group had a clear advantage, exhibiting a distinct sweet fragrance and fresh floral aroma, which aligns with the aforementioned aroma analysis results. The tea samples from the charcoal baking group had a