In recent years, with the increased emphasis on efficient utilization of Tea plant resources, research on improving the utilization of summer tea resources has grown. The high temperatures of summer cause rapid aging of buds and leaves, resulting in a generally lower quality of tea compared to Spring Tea, often with a more bitter taste, which limits further utilization of summer tea. Yellow tea is one of China's six major tea categories, divided into yellow bud tea, small-leaf yellow tea, and large-leaf yellow tea. The characteristic quality of yellow tea is its “yellow liquor and yellow leaf,” with a mellow and sweet aftertaste. Currently, yellow bud tea is mostly produced in early spring, with low yields. Developing a high-quality yellow bud tea from summer fresh leaves can promote the development of yellow tea, enrich its product variety, and extend the production period.

This article builds upon the Mengding Yellow Bud production process by optimizing the pan-firing time, initial yellowing time, and initial yellowing temperature to develop a new summer yellow bud tea product. This aims to provide scientific evidence for the processing of summer yellow bud tea and the comprehensive utilization of summer tea plant resources.

▲ Fengming Mountain Tea Garden, Ya'an, Sichuan Province

01

Materials and Methods

1. Materials and Reagents

Summer fresh leaves of Fuding Dabai tea, picked from the Fengming Mountain production tea garden in Ya'an, Sichuan, with a picking standard of single buds or one bud and one leaf. The experiment was conducted from mid-July to mid-August 2025.

2. Instruments and Equipment

Electric heating forced-air drying oven, Tianjin Test Instrument Co., Ltd.; DL-16 aroma enhancement machine, Shangfeng Tea Machine Factory, Ming District, Ya'an; 6CCH-63 electric wok, Zhejiang Chunjiang Tea Machinery Co., Ltd.; TASI-8601 infrared thermometer, Suzhou Ta'ansi Electronics Co., Ltd.; UV-2300 ultraviolet-visible spectrophotometer, Shanghai Tianmei Scientific Instrument Co., Ltd.

3. Experimental Method

Based on the traditional Mengding Yellow Bud process, the pan-firing and initial yellowing stages were optimized.

① Spreading: Fresh leaves are spread on a cooling trough, 2-3 cm thick, at about 20°C, for 4-5 hours;

② Pan-firing: Wok frying using an electric wok at 180°C, with pan-firing time determined by the specific experimental plan;

③ Initial yellowing: Yellowing is performed by wrapping the leaves in straw paper, placed in an electric heating forced-air drying oven at different yellowing temperatures and times, with the fan turned off and the leaves turned every hour for 2 hours;

④ Second frying: Using an electric wok at 150°C for 5 minutes;

⑤ Secondary yellowing: The leaves are wrapped in straw paper while still hot and placed in the electric heating forced-air drying oven to maintain a leaf temperature of 55 ± 2°C, turning them every hour for 2 hours;

⑥ Third frying: Using an electric wok at 120°C for 5 minutes;

⑦ Tertiary yellowing: The leaves are immediately wrapped in straw paper after the third frying and placed in the electric heating forced-air drying oven to maintain a leaf temperature of 55 ± 2°C, turning them every hour for 2 hours;

⑧ Piling and spreading: Naturally piled and spread on a tray at room temperature for 36 hours at about 20°C;

⑨ Drying: Dried in a constant temperature drying oven at 75°C until fully dry.

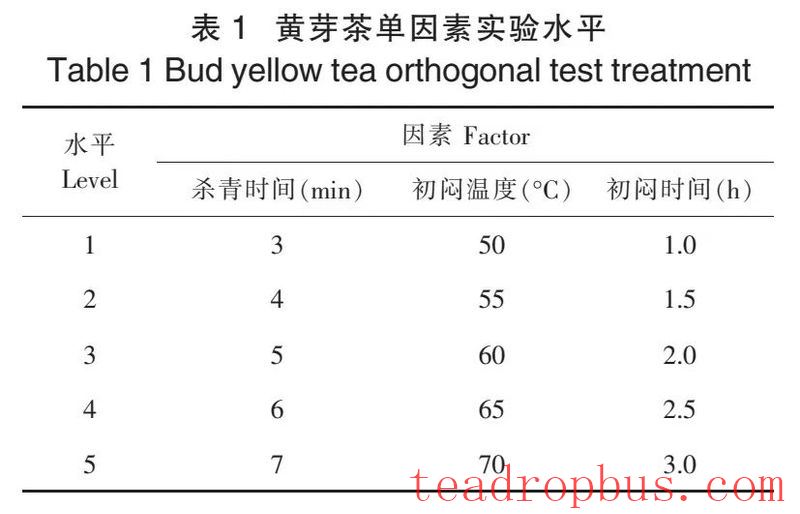

(1) Single-factor Experiment

Referencing the basic processing techniques of traditional Mengding yellow tea, the effects of pan-firing time, initial yellowing temperature, and initial yellowing time on the quality of summer yellow bud tea were examined. The levels of each single factor are shown in Table 1.

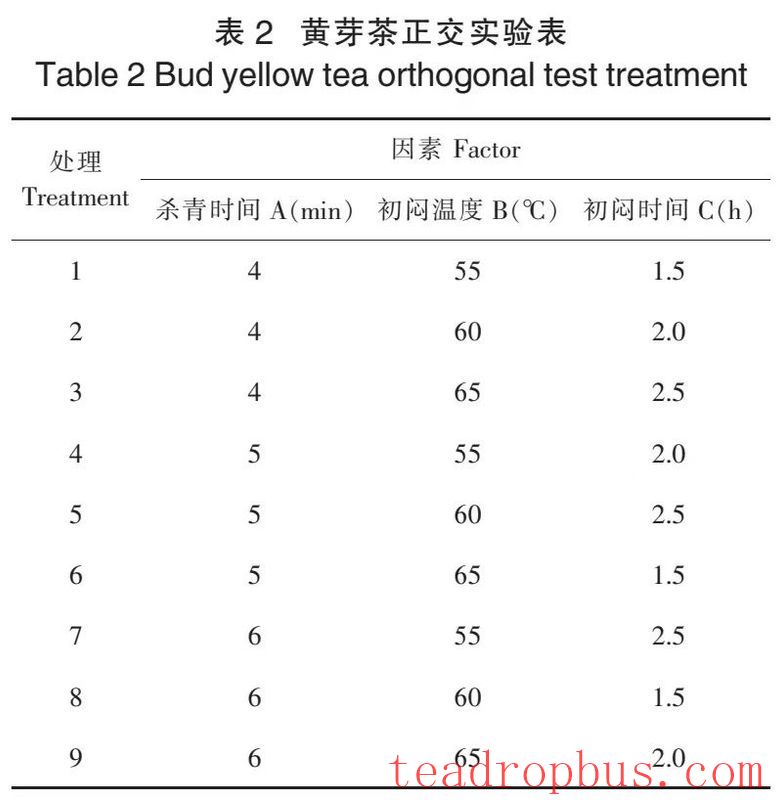

(2) Orthogonal Experiment

Based on the single-factor experiments, pan-firing time (A), initial yellowing time (B), and initial yellowing temperature (C) were selected as factors with three levels each. An orthogonal experiment was designed, using the sensory evaluation and chemical component results under different treatments as the basis. The key steps of the entire process were optimized through orthogonal experiments, using the sensory evaluation results and quality component measurements as evaluation indicators. The experiment environment and equipment remained consistent, with other parameters fixed. Each treatment used 300 g of fresh leaves, repeated three times.

(3) Chemical Component Determination Method

The moisture content of the tea was measured according to GB 5009.3-2016, the total water-soluble extract was measured according to GB/T 8305-2013, the total polyphenol content was measured according to GB/T 8318-2025, caffeine content was measured according to GB/T 8312-2013, free amino acid content was measured according to GB/T 8314-2013, tea pigment content was determined using systematic analysis, and soluble Sugar content was determined using the anthrone-sulfuric acid method. Total chlorophyll and component determination followed the method of Guo et al.

(4) Sensory Evaluation Method

Sensory evaluation of the yellow tea was conducted according to the national standard GB/T 21726-2025. A panel of three senior tea evaluators conducted blind evaluations of the samples.

4. Data Analysis

Experimental data were statistically analyzed using Excel 2025 software, variance analysis was performed using the dps software, and charts were created using Origin 2025.

02

Model Building

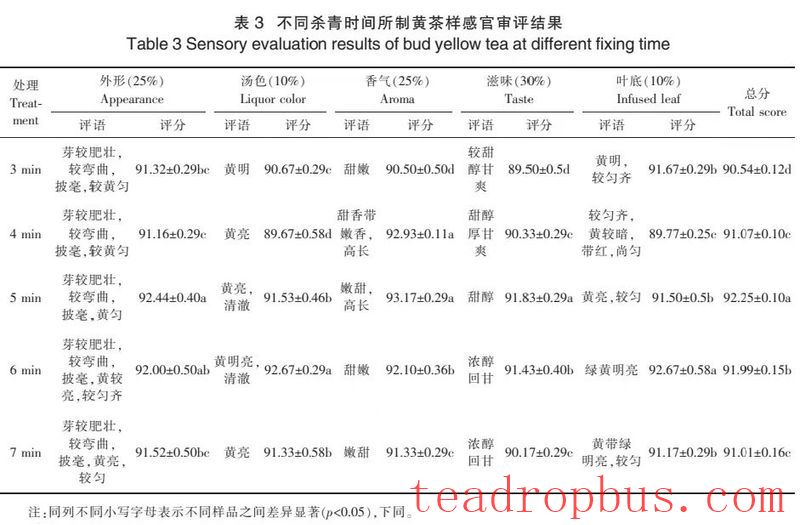

1. Pan-firing Time

Pan-firing is a critical step in yellow tea production. The results showed that pan-firing time affects the sensory quality of yellow bud tea. Yellow bud tea made with a 5-minute pan-firing time had outstanding sensory performance, with the highest scores for appearance, aroma, and taste. As shown in Figure 1, when the pan-firing time was 5 minutes, the tea had lower polyphenol content and significantly higher free amino acid content than other treatments, and the highest soluble sugar content. Overall, the total chlorophyll a, chlorophyll b, and chlorophyll content showed a decreasing trend, with little change in theaflavin content. Caffeine content remained stable but slightly increased with extended pan-firing time. In previous studies, the polyphenol content of summer Green Tea ranged from 24.06% to 30.78%, while the polyphenol content of summer yellow bud tea in this experiment ranged from 22.30% to 22.98%, gradually decreasing with longer pan-firing times. The water-soluble extract content increased with longer pan-firing times, likely due to increased cell wall damage.

Comprehensive analysis of the sensory evaluation scores and quality component measurements suggests that the 5-minute pan-firing treatment had the highest sensory evaluation score and the lowest polyphenol-to