Basic Introduction to Daozhen Green Tea

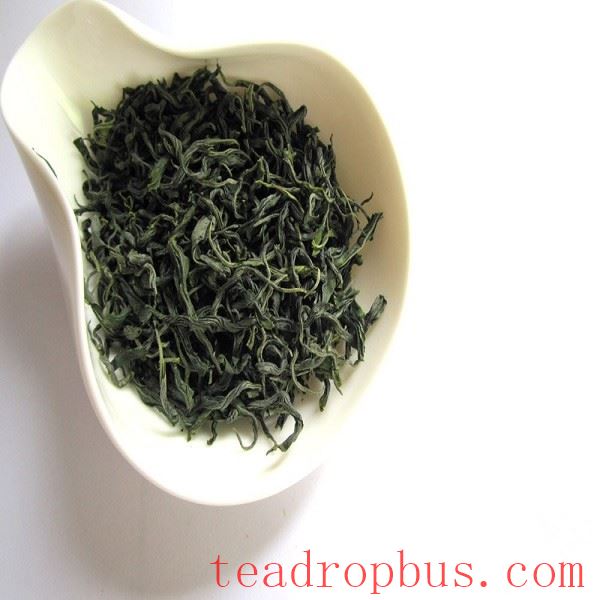

Daozhen tea is a specialty of Daozhen County, Zunyi City, Guizhou Province. The quality of Daozhen tea is excellent, with plump and tender buds that have strong holding power and good fragrance. The color of the processed tea is lustrous green, with a delicate and lasting aroma, clear green infusion, and a fresh and mellow taste.

The climate and soil in Daozhen are very favorable for the growth of tea trees. The tea produced here has an exceptional quality, with plump and tender buds that have strong holding power and good fragrance. The color of the processed tea is lustrous green, with a delicate and lasting aroma, clear green infusion, and a fresh and mellow taste.

Nutritional Value

Through investigations by research institutions such as the Institute of Geochemistry of the Chinese Academy of Sciences, the Guizhou Tea Research Institute, and the Testing Center of Wuhan University, it was confirmed that Daozhen is one of the few areas in China rich in Selenium (Se) and strontium (Sr). The content of these two trace elements in the tea produced here is among the highest in the country, with 1.5-4 PPm of selenium and 7 PPm of strontium per gram of tea. Regular consumption of this tea can help prevent cardiovascular diseases, diabetes, and resist the transformation of cancer cells. It also has the effects of delaying aging, enhancing vision, and eliminating toxic metals like aluminum and mercury from the body. It is a preferred health drink for coastal and Southeast Asian regions deficient in selenium.

The tea garden area in Daozhen County, home to the Gelao and Miao ethnic groups, covers 30,000 mu (approx. 2,000 hectares).

History and Folk Customs

Green Tea is the oldest type of tea. The practice of collecting wild tea leaves, drying them in the sun, and storing them can be considered the beginning of a broad sense of green Tea processing, dating back at least 3,000 years. However, true green tea processing began with the invention of steaming in the 8th century, followed by the invention of stir-frying in the 12th century. Since then, green tea processing techniques have matured and have been continuously improved. The production of green tea can be simply divided into three steps: fixation, rolling, and drying, with the key step being the first process, fixation. During this process, enzymes in the fresh leaves are deactivated by heat, preventing the oxidation of polyphenols and redness of the leaves. As water evaporates, the low-boiling-point aromatic compounds that give the leaves a grassy smell also volatilize, improving the aroma of the tea.

Manufacturing Method

1. Fixation

Fixation plays a decisive role in the quality of green tea. By applying high temperatures, the characteristics of enzymes in fresh leaves are destroyed, stopping the oxidation of polyphenols and preventing the leaves from turning red. At the same time, some of the water in the leaves evaporates, making them softer and more pliable for rolling. As the water evaporates, low-boiling-point aromatic compounds that give the leaves a grassy smell also volatilize, improving the tea's aroma. Except for special teas, this process takes place in a fixation machine. Factors affecting the quality of fixation include temperature, leaf volume, type of fixation machine, time, and method of fixation. These factors are interrelated and influence each other.

2. Rolling

Rolling is a process in which the shape of green tea is formed. Through external force, the leaves are broken and rolled into strips, reducing their size and making them easier to Brew. At the same time, some of the tea juice is squeezed out and coats the surface of the leaves, which is important for enhancing the flavor concentration of the tea. There are two types of rolling methods for green tea: cold rolling and hot rolling. Cold rolling involves rolling the fixed leaves after they have cooled down; hot rolling is done immediately after fixation while the leaves are still warm. Tender leaves should be cold-rolled to maintain the bright yellow-green color of the infusion and the tender green appearance of the leaves, while older leaves should be hot-rolled to ensure tight strips and reduce breakage. Currently, except for handmade specialty teas, the rolling process for mass-produced green teas is mechanized.

3. Drying

The purpose of drying is to evaporate moisture, shape the leaves, and fully develop the tea's aroma. Drying can be done through baking, stir-frying, or sun-drying. In the production of green tea, the leaves are usually first baked and then stir-fried. Because the moisture content of the rolled leaves is still quite high, if they were directly stir-fried, they would quickly clump together in the stir-frying pan and the tea juice might stick to the pan walls. Therefore, the leaves are first baked to reduce their moisture content to a level suitable for stir-frying.