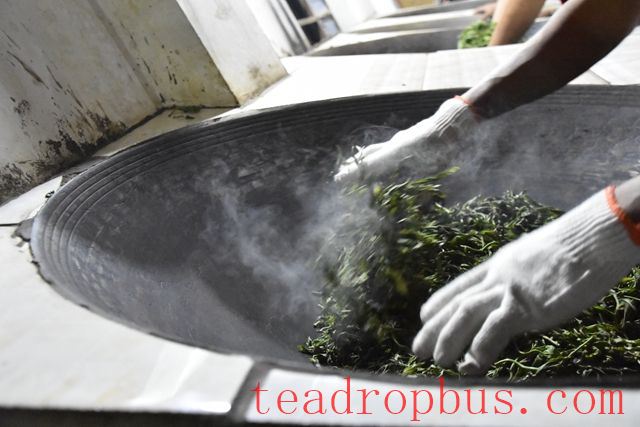

In making Pu'er Tea, fixation is one of the most familiar steps and a critical factor in determining its quality. “Fixation” accurately refers to the destruction of the tea Leaf's tissues, enabling the rapid transformation of its internal substances into the unique qualities and flavors that define various tea types under high-temperature conditions. The temperature for fixation is particularly important. Pu'er tea has specific requirements for fixation temperature.

What is the Temperature for Fixation in Pu'er Tea?

The temperature for fixation in Pu'er tea needs to be raised above 80 degrees Celsius within a short time in the fixation pan;

Li Xingchang, an inheritor of the intangible cultural heritage of Pu'er “tribute tea” production techniques, believes that there are two key points:

First, the pan temperature must be appropriate, allowing the fresh leaf temperature to rise rapidly as the pan temperature decreases;

Second, one must be proficient and master the four-character mantra for fixation: “toss,” “cover,” “shake,” and “throw.” When to “toss,” “cover,” “shake,” and “throw”? “This depends on experience and tactile sense to perceive the pan temperature and leaf temperature, which allows one to discern the degree of moisture loss in the fresh leaves.”

Both under-fixation and over-fixation can have fatal effects on the quality of Pu'er tea.

Under-fixation does not achieve the required deactivation of active enzymes in the leaves and fails to effectively release the aromatic compounds, resulting in a heavy grassy flavor during later tasting, affecting the taste of the tea.

Therefore, when fixing, one should adapt to the characteristics of the tea. If the leaves are soft and have low water content, the degree of fixation can be reduced; if the leaves are hard and have high water content, the fixation should be more intense.

What is the Purpose of Fixation in Pu'er Tea?

The primary purpose of fixation in Pu'er tea is to destroy and deactivate the oxidase enzymes through high temperatures, inhibiting the enzymatic oxidation of polyphenols in the fresh leaves. It also evaporates some of the water content, making the leaves softer for rolling and shaping, while eliminating the “greenish smell” and promoting the development of a pleasant aroma.