“I heard from a ‘master' that when stir-frying to stop oxidation, it must be done at a low temperature slowly, only then can the Pu'er Tea release its fragrance!”

“Actually, you can try shaking to enhance the aroma during the withering of fresh Pu'er leaves; the effect of enhancing the aroma is quite good!”

These kinds of serious cognitive errors have been troubling the general public's understanding of Pu'er tea. Can the processing of Pu'er tea imitate other types of tea? What exactly is the correct tea-making process?

Today, Lu Li will discuss the unorthodox changes in Pu'er Tea processing on the tea mountains over the past two years.

Rigorous Scientific Chemical Reactions in Tea

After being stir-fried and rolled, fresh leaves dried under sunlight are collectively referred to as “sun-dried green rough tea.” According to national standards, Yunnan's unique Pu'er tea must use sunlight for drying to be called Pu'er tea.

Sun means sunlight, green refers to the fresh leaves, combined, they mean the rough tea after sun-drying. One point that needs correction is that some tea enthusiasts think that sun-drying is a method of stopping oxidation, but sun-drying is actually the drying method for rough tea.

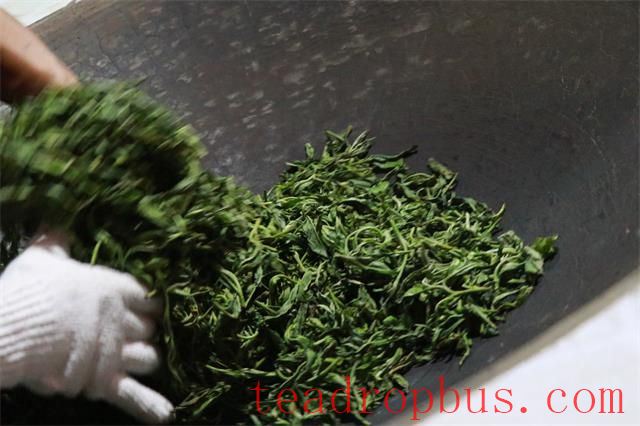

In the process of making Pu'er tea, it typically goes through the following steps: the fresh leaves are picked by tea farmers in the morning, spread out for about 8 hours, and once the water content in the stems reaches balance, they are placed into an iron pot for stir-frying to stop oxidation, causing further evaporation of the water in the leaves.

After briefly setting them aside to cool down, the leaves are rolled to increase the rate of extraction during brewing and transform the leaves from “sheets” to “strips.” Finally, after 5 hours of air-drying, the original yellow-green fresh leaves become dark green and grayish sun-dried green rough tea.

From an overall perspective, the initial processing process that Pu'er fresh leaves undergo, from picking to spreading, stopping oxidation, cooling, rolling, and drying, is a process where the leaf moisture continuously decreases, and it is also a series of rigorous scientific chemical reactions in tea.

High-Temperature Stir-Frying Transforms Tea Enzymes

The green taste, also known as the grassy taste or the astringent green taste, is the natural flavor of plants, which requires the step of stopping oxidation to handle.

The essence of stopping oxidation is to use high-temperature chemical changes to destroy the tissue of the fresh leaves, allowing the water to evaporate fully, achieving the purpose of diminishing the green taste and revealing the aroma.

This is the general consensus in the industry regarding stopping oxidation, but how does high temperature transform the fresh leaves in more detail? From a more detailed microscopic perspective, we find the decisive substance in the process of stopping oxidation – tea enzymes.

Enzymes are large molecules with catalytic functions, primarily composed of proteins, whose biological activity is influenced by factors such as temperature, humidity, and pH value. They control the conversion speed of tea without changing the direction of conversion.

In other words, enzymes are healthy biological catalysts.

In the high-temperature environment of stopping oxidation, the protein molecular structure of enzymes is completely destroyed, the polyphenol oxidase in the fresh leaves loses its activity, and enzyme-catalyzed oxidation is further inhibited.

After a series of non-enzymatic reactions, most of the grassy smell of the fresh leaves has faded, and the color, aroma, and taste characteristics of Pu'er tea gradually emerge. The leaves also become softer, providing convenience for subsequent rolling and compression molding processes.

In summary, if making Pu'er tea is compared to building a skyscraper, then the step of stopping oxidation is like demolishing the existing building and laying part of the foundation, providing the first step for subsequent construction.

The purpose of stopping oxidation is to destroy the original tissue structure of the fresh leaves, allowing the water in the fresh leaves to continuously evaporate, shaping their physical form, and preparing for subsequent sun-drying and fermentation processes.

The Essential Differences Between Sun-Drying, Stir-Drying, Oven-Drying, and Oven-Stopping Oxidation

Compared to stopping oxidation, the essence of sun-drying is very simple – it involves exposing the rough tea after stopping oxidation to sunlight again. Once the color of the strips changes from yellow-green to dark green, they are re-rolled, and when the moisture content drops to around 10%, the entire sun-drying process is completed.

One point that needs clarification is that not all sun-drying nowadays is carried out under direct sunlight. If there is continuous mountain rain, processing bases will consider oven-drying to allow the sun-drying of the leaves to continue.

Some tea enthusiasts may ask here, isn't the oven-drying mentioned above oven-stopped oxidation Pu'er tea? This leads to a key question – how to distinguish between sun-drying, stir-drying, oven-drying, and oven-stopping oxidation?

The most fundamental difference among these three lies in temperature. From a comparative perspective, the higher the temperature, the less beneficial it is for the subsequent transformation of the tea. Sun-drying occurs naturally and can fully preserve the active enzyme substances in the tea.

On cloudy and rainy days when sun-drying cannot be carried out, oven-drying technology comes into play. Normal oven-drying is always carried out at a low temperature, usually not exceeding 60°C. Although this low-temperature drying takes a long time, it can preserve the activity of the tea as much as possible.

The term “oven-stopping oxidation,” which differs by just one character from oven-drying, doesn't involve such meticulous work. The temperature for oven-stopping oxidation is 80 to 120°C, far higher than the normal range of 60°C.

The entire process of oven-stopping oxidation is very fast, resulting in finished products with a bright green appearance, a high aroma, and a beautiful form. However, it severely depletes the activity and potential of the tea.

Pu'er tea cakes made using the sun-drying process not only have a tightly compacted surface and tightly twisted strips, but also have a noticeable tea aroma. After storing them for three to five years, the tea soup becomes rich in gel-like texture, the finish is sweet and refreshing, and the durability of the Brew is excellent.

Pu'er tea cakes made using the oven-stopping oxidation process not only have a loose surface and untwisted strips, but the characteristic of becoming more fragrant with age is also significantly reduced. After storing them for three to five years, the tea soup is bitter without sweetness, lacks sweetness and refreshment, and the durability of the brew is extremely poor.

The reason why Pu'er tea made using the oven-stopping oxidation process has poor aging effects is that this technique is actually a manufacturing process for Green Tea and should not be used for Pu'er tea.

Due to the high-temperature drying, Pu'er tea has a high aroma when freshly made, which is highly deceptive. Therefore, unscrupulous merchants often mix oven-stopped oxidation tea leaves into Pu'er tea to create the illusion of a new tea with a strong aroma.

Stir-drying is a traditional manufacturing method for green tea. The repeated rolling by the tea maker causes the tea in the pot to continuously wilt, and the water in the tea evaporates rapidly to achieve the purpose of interrupting the fermentation of the tea and retaining all the essence within the leaves.

The key difference between Pu'er tea and green tea lies in the temperature used during manufacturing. Green tea uses high-temperature stir-drying to achieve a high aroma but cannot