Compared to a lidded cup, the advantage of a Purple Clay Teapot lies in its porosity. The unique structure of the clay allows it to be porous yet not permeable to water, making it the preferred tool for brewing Tea.

What Factors Influence the Porosity of a Purple Clay Teapot?

The temperature during firing and the clay's responsiveness to heat play crucial roles. If the clay does not reach its optimal firing temperature, it will be underfired, and at this stage, the teapot will exhibit the best porosity. Pouring hot water into such a pot would cause beads of moisture to quickly appear on its surface. However, using an underfired pot for brewing tea is not ideal. On the other hand, overfiring the pot results in higher crystallization and reduced porosity, which negatively affects its breathability.

How can one determine the appropriate firing temperature for a particular type of clay? Potters typically create several circular test pieces and subject them to different temperature ranges to identify the temperature that yields the best color and quality.

The characteristics of the clay also influence its porosity. Among the three main types of clay, duan (segment) clay has the highest sand content and, therefore, the best porosity compared to zini (purple clay) and hongni (red clay). Zini ranks second, while hongni, with less sand content (often referred to as “more flesh than bone”) and a softer texture, has the lowest porosity after firing. This high density makes it less breathable, which is precisely why it is the most suitable choice for brewing Tieguanyin tea, as its lower porosity helps to better extract the aroma from the leaves.

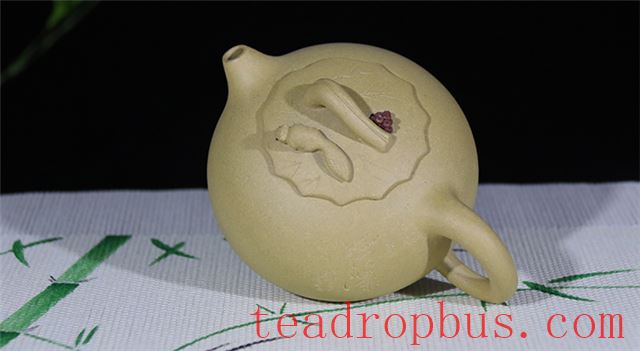

Duan Clay / Image: ChaWoNet

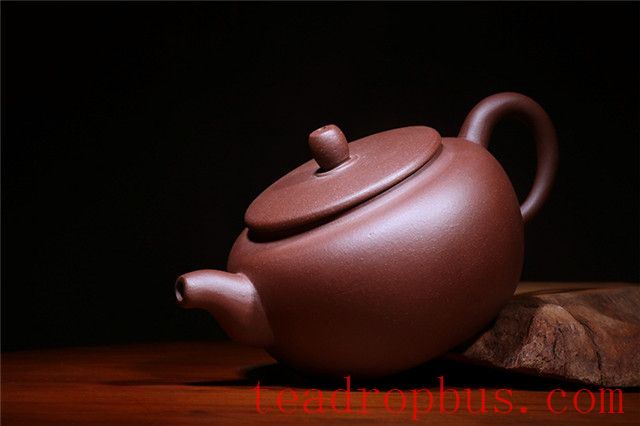

Zi (Purple) Clay / Image: ChaWoNet

Hong (Red) Clay / Image: ChaWoNet

The method used to process the clay also impacts its porosity. When transforming raw purple clay ore into usable clay for making Teapots, if a machine is used for kneading the clay, the high force can destroy the sand content within the clay. In contrast, manually grinding and pounding the clay preserves much of its sand content. More sand means more gaps between particles, leading to significantly enhanced porosity after firing!