In recent years, the foundational research into Tea processing has become increasingly sophisticated, with a clearer understanding of key process characteristics and the physicochemical properties of the products at various stages. Advanced technologies such as spectral techniques, electrochemical methods, machine vision, electronic noses, and electronic tongues are constantly improving to reflect the quality of tea. These advancements have propelled Tea processing technology towards digitalization and intelligence.

1. Detection and Grading of Fresh Leaf Quality

In the tea processing process, determining the quality grade of fresh leaves is a prerequisite for setting technical parameters. Using near-infrared spectroscopy, with moisture content, total crude fiber, and total nitrogen as indicators of leaf quality, an online evaluation model for raw fresh tea leaves was established, providing an accurate and fast new method for assessing the quality of raw fresh tea leaves.

Researchers constructed a BP neural network model using geometric features (such as area, perimeter, major axis length, and minor axis length) and texture features (such as contrast and smoothness) of fresh tea leaf images to accurately classify the leaves by tenderness grade. By designing an intelligent sorting system for fresh tea leaves and building a convolutional neural network discrimination model based on a seven-layer structure, smart recognition and grading of fresh tea leaves can be achieved.

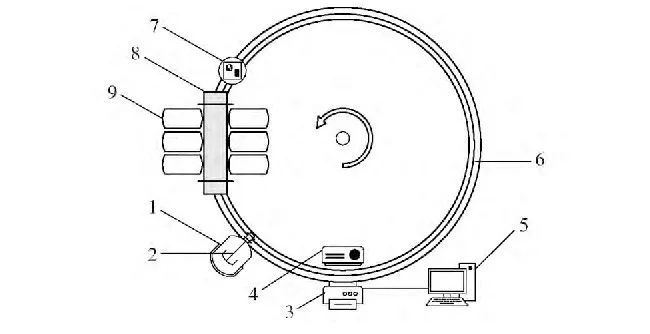

Schematic Diagram of the Smart Sorting System for Fresh Tea Leaves

2. Analysis and Detection of Withering Degree

Withering is an important step in tea processing. Real-time, accurate, and non-destructive detection of the moisture content during the withering process is crucial for achieving precise control over the moisture content of the withered leaves, which is significant for the digitalized and intelligent production of the withering step. Using near-infrared spectroscopy, a method for predicting the moisture content of green tea withered leaves was proposed. By converting the near-infrared spectra of fresh leaf samples into paired data points and using joint interval partial least squares to establish a moisture content prediction model, rapid prediction of the moisture content of green tea withered leaves can be achieved. Utilizing near-infrared spectroscopy through VCPA-GA to extract characteristic wavelengths and establish PLSR and support vector regression prediction models allows for accurate and non-destructive prediction of the moisture content of green tea withered leaves, solving the problem of quantitative prediction of the moisture content of withered leaves and providing important guidance for the digitalization of green tea processing equipment.

3. Detection and Discrimination of Withering Degree

In actual production, accurately assessing the degree of withering is a prerequisite for improving the quality of Black Tea. A technique that fuses image and spectral information with linear discriminant analysis and PLS was used to establish a linear discriminant model for the degree of withering and a PLS prediction model for the ratio of catechins to amino acids, achieving a discrimination accuracy rate of 94.64%. This method enables digital discrimination of the degree of withering in black tea.

Additionally, researchers combined miniature near-infrared spectroscopy with smartphones to develop an Elman neural network (ENN)-based prediction model for the moisture content of withered leaves. This method, which combines ENN with principal component analysis, not only extracts spectral features but also processes dynamic information, improving the model's anti-interference capability and training efficiency, providing a portable, accurate, rapid, and non-destructive method for predicting the moisture content of withered leaves.

(a) Miniature Near-Infrared Spectrometer; (b) Spectral Acquisition Interface on a Smartphone

4. Discrimination and Control of Fixation Degree

By accurately judging the moisture content of fixed leaves, the degree of fixation in green tea production can be effectively detected. Using visible-near infrared spectroscopy and hyperspectral imaging technology, high spectral information from Longjing 43 fixed leaves was preprocessed and feature extraction was performed to establish spectral and imaging detection models for moisture content. This provides technological support for the digital online detection of moisture content in fixed green tea leaves. Through machine vision, the color and texture features of the product during microwave fixation can be monitored in real time. By establishing ELM, genetic neural network, and CNN models, the moisture content, polyphenol, and amino acid content of the fixed leaves can be detected online. This method has good application prospects for the rapid detection of tea quality after fixation and for digitalized tea fixation operations.

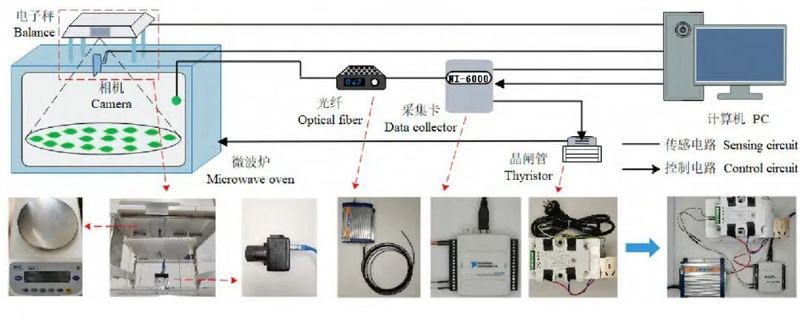

Study on Quality Changes and Prediction During Microwave Fixation of Tea Based on Machine Vision

5. Detection and Discrimination of Kneading Degree

In recent years, research on kneading has mainly focused on digitalization and foundational research, including studies on the basic physical properties, appearance texture, mechanical properties, electrical properties, optical properties, microscopic structure, and changes in major chemical components during the kneading process. Relevant analyses have preliminarily established evaluation methods for the degree of kneading and digital control strategies for kneading machines.

6. Detection and Discrimination of Fermentation and Piling Quality

1. Detection and Discrimination of Fermentation Quality

(1) Research on the Method of Analyzing Fermentation Quality from a Visual Perspective. Using machine vision technology, the changes in the RGB, Lab, and HSV color spaces of images during the fermentation process of black tea were analyzed. Color feature parameters were used as inputs to establish a nonlinear quantitative prediction model for tea pigments, and computer image color features and random forest models or SVM nonlinear algorithms could digitally evaluate the quality indicators during the fermentation process of black tea.

(2) Research on Optical Spectroscopy for Detecting Physicochemical Components. In recent years, this field has primarily established quantitative prediction models for major internal components (theobromin, thearubigin, catechins, Caffeine, and soluble sugars). The distribution of key quality indicators of black tea at different times was visualized, allowing for real-time detection of changes in key internal components during the fermentation process and their distribution, providing technological support for the visualization and digitalization of fermentation information.

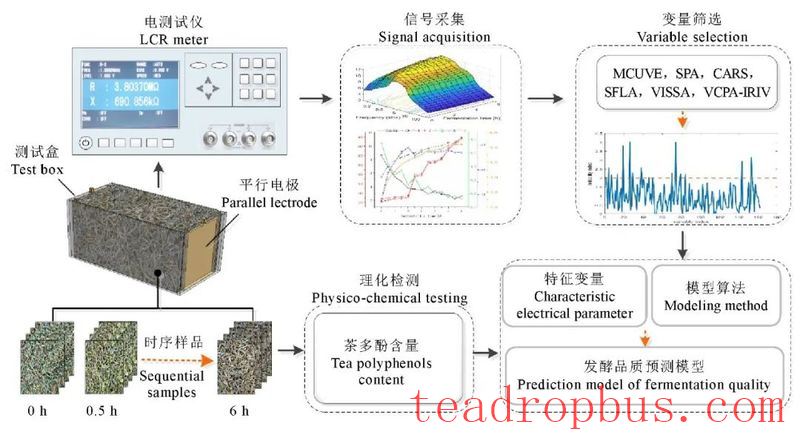

(3) Application of Electrical Characteristic Technology in Fermentation Quality Detection. Using semi-finished products of gongfu black tea as the research object, electrical characteristic detection technology combined with chemometrics was utilized to construct a prediction model for the polyphenol content of fermented leaves. The changing patterns of electrical parameters (parallel equivalent capacitance, loss factor, and reactance) of fermented leaves were explored. Experiments showed that electrical characteristic detection technology can be used for the digital prediction of polyphenol content in black tea during the fermentation process.

Workflow for Electrical Characteristic Information Collection and Analysis

(4) Application of Multivariate Information Fusion Technology in Fermentation Quality Detection. A low-cost micro near-infrared spectroscopy and a laboratory-made computer vision system were used for online rapid detection of black tea fermentation quality. PAC-SVM quantitative prediction models for catechins and theaflavins were established, and color, spectral, and data fusion information were used to digitally characterize the degree of fermentation in black tea.

2. Detection and Discrimination of Piling Quality

Using a near-infrared spectrometer, spatial distribution maps of piling raw materials at different degrees of piling were obtained. There was no cross-distribution of piling raw materials of dark brick tea at different degrees of piling in space, thus achieving digital prediction of the degree of piling.

7. Detection and Discrimination of Drying Degree

The drying temperature, drum rotation speed, initial moisture content of the dried product, and predicted time were used as inputs, and moisture content as output, to establish tea moisture content prediction models during the drying process using multiple linear regression, BP neural networks, Elman neural networks, and particle swarm optimization of Elman neural networks. The excellent predictive performance of this method has guiding significance for digitalized tea drying operations.

This excerpt is taken from “Research Progress in Digital Processing Technology for Tea,” published in China Tea, Issue 8, 2025, pp. 1-8. Authors: Shen Shuai, Yuan Haibo, Zhu Hongkai, and Jiang Yongwen