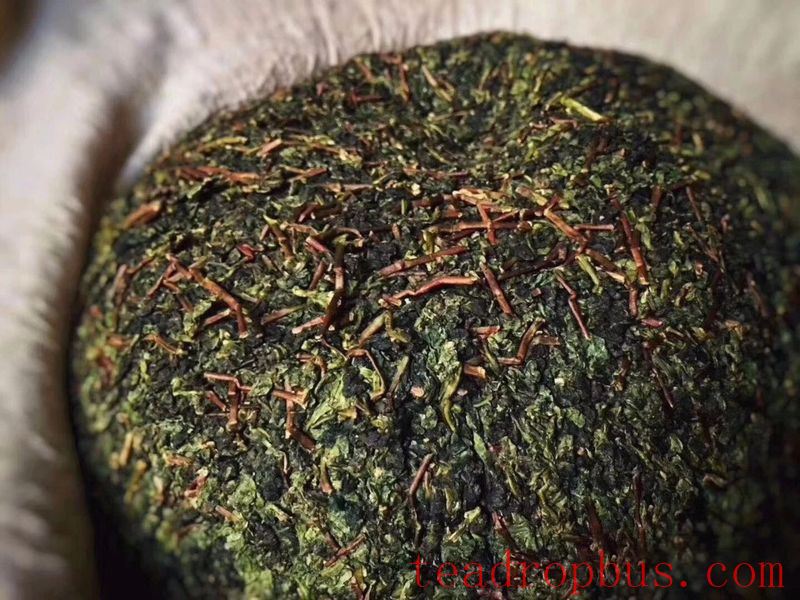

Anxi Tieguanyin is renowned both at home and abroad, often referred to as the “King of Chinese Teas.” Its initial processing differs from that of black Tea and Green Tea, being much more complex. It draws on the principles of full fermentation for black tea and non-fermentation for green tea. During the initial processing, the whole leaf structure is not entirely destroyed, but the edge tissues are slightly damaged. The aim is to ensure that the contents of the cells do not completely change, while some undergo oxidation, resulting in a reddish-brown color at the edges of the leaves and a light green in the center. This creates a unique appearance known as “green leaves with a red border,” commonly referred to as semi-fermented. Through this intricate process, distinctive color, aroma, and flavor are developed.

Withering Stage

The withering technique is highly technical and flexible, playing a crucial role in the formation of the color, aroma, and taste of Oolong Tea during initial processing. Commonly known as “withering,” it can be divided into indoor withering (cooling), sunlight withering (sun-drying), heated withering, and controlled withering by humans.

1. Indoor Withering (Cooling): Fresh leaves are spread out on a bamboo mat and placed on a cooling rack, turning them 2-3 times as needed to ensure even withering. Cooling is usually not carried out independently but combined with sun-drying. Its primary functions include: dispersing surface moisture and leaf temperature to keep the tea fresh; regulating sun-drying time to slow down the evaporation of water; and serving as a remedial method for insufficient sun-drying. The appropriate level of cooling is achieved when the tender stems are green and full of water, and the leaf surfaces appear fresh without any excess moisture.

2. Sunlight Withering (Sun-Drying): This utilizes solar energy to cause moderate dehydration of the fresh leaves, activating enzymes, which is essential for developing the aroma of Oolong tea and removing the grassy odor. It also prepares the leaves for shaking. Sun-drying requires soft, oblique sunlight and thin, even spreading of the leaves. If necessary, “two rounds of cooling and two rounds of sun-drying” can be performed, lasting 10-30 minutes, with the leaves turned 2-3 times during this period. Sun-drying is considered complete when the leaves lose their luster, turn a darker shade of green, the top leaves droop, the stems bend without breaking, and have a springy feel. After sun-drying, the leaves should be cooled again to restore their vitality.

3. Heated Withering: On rainy days, heated withering can be employed, such as using a withering trough where the air temperature does not exceed 40°C and the leaf temperature does not go beyond 30°C. The leaves are spread 15-20 cm thick and turned every 10-15 minutes. This process lasts about an hour.

4. Human-Controlled Withering: Based on the requirements of Oolong tea processing, advanced equipment is used to control the temperature and humidity during withering, achieving excellent results.

Shaking Process

Shaking is a unique operation specific to Oolong tea and is critical to its characteristic development.

1. Functions of Shaking: Breaking the edge cells to accelerate enzymatic oxidation; promoting the “flow of water” within the tea leaves; changing the way moisture evaporates, allowing some of it to escape through damaged cells; providing external force for various internal changes within the leaves.

2. Methods of Shaking: Initially, the number of rotations (time) is gradually increased; cooling periods become longer over time; the thickness of the spread leaves becomes thicker gradually.

3. Observing the Tea: A four-step process involving “looking, smelling, touching, and examining.”

4. The content of observing the tea primarily includes the leaf shape, color, temperature, and aroma.

5. Special Withering Methods for Specific Varieties

The variety-specific characteristics of the finished tea are partly inherent in the fresh leaves, such as the distinctive qualities of Tieguanyin or the aromatic compounds in Huangjinguui. Others are preserved, transformed, and synthesized during the withering process. During withering, methods such as light sun-drying, gradual increase in shaking intensity, and measures to “retain moisture and freshness” are typically employed.

Fixation Process

The internal quality of Oolong tea, including its “color, aroma, and taste,” is largely formed during the withering stage. The fixation process is a transitional step that serves as a bridge between different stages. It stops the ongoing enzymatic oxidation, stabilizing the already developed qualities, and facilitates further moisture loss, making the tea suitable for rolling and baking. Fixation has a certain influence on the final quality.

Functions of Fixation

1. The primary function of fixation is to rapidly and thoroughly deactivate enzyme activity, preventing further “fermentation” and excessive browning. 2. It continues the dispersion of moisture, preparing the tea for shaping. 3. High temperatures cause partial cell rupture, releasing cell sap onto the leaf surface, reducing low-boiling-point grassy odors, revealing higher-boiling-point fragrances, presenting a new tea aroma, reducing chlorophyll, and transforming other pigments to varying degrees.

Methods of Fixation

1. Appropriate high temperatures, initially high then lowered; 2. Primarily covered fixation; 3. Rapid and short duration.

Extent of Fixation

The fixed leaves turn dark yellow-green, losing their luster. The leaf surfaces and stem skins develop wrinkles, the leaves become soft, the top leaves droop, and they can be lightly formed into a ball when squeezed. The moisture loss rate is 16-22%. The extent of fixation should consider the following factors: 1. Degree of fermentation; 2. Variety; 3. Season; 4. Tenderness.

Rolling and Baking Stage

Rolling

1. Functions of Rolling: During rolling, the primary change is in the shape of the leaves. Inside the rolling container, the leaves are subjected to flat pressure and curved pressure. As the tea mass rolls, the leaves experience compression, forming wrinkles and curling into strips. When passing through the area of maximum pressure, some cells twist and rupture, releasing tea juice onto the leaf surface, increasing the adhesiveness of the leaves. Water-soluble substances contribute to the concentration of the tea liquor. 2. Method of Rolling: Rolling should employ the method of “hot rolling, appropriate heavy pressure, rapid and short duration.” The amount of leaves loaded should be suitable. Immediately after rolling, the clumps should be loosened to dissipate heat and moisture, and the leaves should be baked promptly.

Initial Baking

Initial baking, the first round of baking,