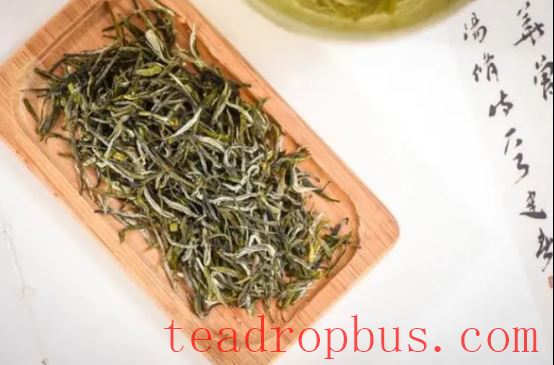

Yangxian Xueya, a specialty of Yixing City, Jiangsu Province, is produced within the national Taihu Lake scenic and tourist area. Its name is derived from Su Shi's poem: “Xueya I seek in Yangxian.” Yangxian Xueya has a tight, straight appearance with a vibrant green color and visible downy hairs. It has a clear and elegant aroma, a fresh and mellow taste, a bright and clear liquor, and tender, intact leaves at the bottom of the cup. The authoritative Tea expert Lu Yu considered Yangxian tea to be “the most fragrant in the world,” suitable for imperial tribute, thus it was listed as a tribute item. In Lu Yu's Tea Classic, it is recorded that “In Yixing County, Changzhou Prefecture, tea grows on the northern peak below the overhanging cliffs of Jun Mountain,” indicating the renown of Yangxian tea during the Tang Dynasty.

I. Origin Environment

Yangxian Xueya is a famous local specialty of the southern Yangxian scenic area in Yixing City, Jiangsu Province. Yixing City is located at the southernmost tip of Jiangsu Province, bordering Taihu Lake to the east, Zhejiang Changxing and Anhui Guangde to the south, Liyang to the west, and Wujin to the north. The city has convenient transportation and a developed economy. The southern part of Yixing is hilly, with overlapping mountains and high terrain. There are numerous karst caves in the region, giving it the reputation of being a “world of caves,” and it is also known as the “bamboo sea” for its dense bamboo forests that stretch across the slopes and hills. Yangxian Xueya is produced within the national Taihu Lake scenic and tourist area.

II. Production Process

01 Raw Material Harvesting

The harvesting period for Yangxian Xueya is around Qingming (Pure Brightness) to Guyu (Grain Rain), and the standard is one bud and one leaf, requiring plump buds which contain the richest substances. For top-grade tea, single buds are picked, choosing plump and full buds without disease, pests, frost damage, fish-shaped leaves, or scales. First and second grade fresh leaves mainly consist of one bud and one leaf, either initially unfolded or half-unfolded. Fresh leaf harvesting requirements include: young, uniform, clean, and fresh, without fish-shaped leaves, purple buds, single leaves, opposite leaves, old leaves, or non-tea contaminants.

02 Fresh Leaf Handling

Low temperature and high humidity are required, with thin layers and long periods of spreading. The environment must be clean, dry, free from contamination, well-ventilated, and cool, with an indoor temperature of 20-25°C and relative humidity of 70%. Low temperatures are beneficial for the transformation of the quality of the internal substances in the tea leaves, while increased humidity is conducive to moderate spreading of the plump buds, ensuring uniformity inside and outside the leaves. After picking, the fresh leaves should be sorted by grade and spread thinly on bamboo mats (about 2-3 cm thick) for 4-5 hours until they have lost about 5-8% of their weight, with a moisture content of approximately 72%, after which they can proceed to the fixation step.

03 Fixation

Fixation is the first step in making Yangxian Xueya and is very critical. The leaves must be fixed evenly and thoroughly, changing color to a darker shade, becoming softer, slightly sticky, with the disappearance of the grassy smell and the emergence of tea fragrance. Fixation should result in a moisture content of 56-58% in the fixed leaves. Using an 80-type drum fixer ensures good ventilation and rapid evaporation of water vapor, resulting in a vibrant green color and elegant aroma in the finished tea. After fixation, the leaves must be quickly cooled with a fan to dissipate moisture and lower the temperature, maintaining a bright green color and preventing yellowing of the buds.

04 Light Rolling

After fixation and complete cooling, the initial rolling process begins. This step can be done manually or using machinery. To ensure the integrity of the tea, the initial rolling involves rolling without pressure for 3-5 minutes, gradually increasing the pressure for another 3-5 minutes, then reducing the pressure and rolling without pressure for 2 minutes before removing the tea from the container. The total time for initial rolling is 8-10 minutes. If a single rolling is used, too light rolling will result in loose strands in the finished tea, while too heavy rolling will damage the integrity of the leaves and darken their color.

05 Initial Drying

After breaking up the clumps, the initially rolled leaves undergo initial drying at a temperature of 90-110°C for 5-8 minutes, losing 20% of their weight and having a moisture content of 45%. The leaves should not easily form a ball when grasped, and should naturally disperse when released, with elasticity, indicating appropriate initial drying.

06 Re-Rolling

Once the initially dried leaves have cooled sufficiently, they are placed back into the rolling machine. Re-rolling starts with 2-3 minutes of rolling without pressure, followed by 4-5 minutes of gradual pressure, and another 2-3 minutes of rolling without pressure, repeated twice before removing the tea from the container.

07 Shaping

The re-rolled leaves are promptly separated and shaped, lasting 5-8 minutes, until the tea has a tight, straight appearance, with a vibrant green color and an emerging aroma, and a moisture content of 30%, after which they are removed from the pot.

08 Refining and Drying

The shaped tea is cooled and softened before being placed directly in the pan, spread out, shaped and rolled until it feels slightly firm to the touch, at which point the rolling can be intensified until the leaves become tight and straight, revealing their tip. When 80% dry, rolling is stopped, with gentle handling, lasting 5-8 minutes, and the moisture content should be around 10% before removing the tea from the machine. Final drying is usually done using a 6CH-1 type automatic dryer for high-quality teas, operating at a temperature of around 70-80°C for 10-15 minutes, controlling the moisture content of the dried tea to within 6%. The dried tea should be promptly cooled and then sorted for final processing.

09 Manual Finishing

The finishing of all grades of Yangxian Xueya is primarily done by hand, using wind selection or manual sifting to remove broken pieces and fragments, and sieving out the tea dust before packaging.

III. brewing Method

01 Teaware

When brewing Yangxian Xueya, it is generally recommended to use transparent tempered glass cups, white porcelain cups, or tea bowls, which help to highlight the vibrant green color of the leaves and the tea liquor.

02 Water Quality

The water quality for brewing Yangxian Xueya should be excellent. It is recommended to use high-quality mineral water or purified tap water, but avoid alkaline water, as it can cause the tea liquor to darken and turn yellow.

03 Water Temperature

Water that has just boiled is suitable for brewing, resulting in a perfectly fresh and brisk tea liquor. The water temperature should be around 80-85°C; especially for high-quality Yangxian Xueya, higher temperatures can easily damage the leaves, turning them yellow. The polyphenols in the tea leaves can also oxidize at high temperatures, causing the tea liquor to turn yellow, and the aromatic compounds can volatilize, leading to a loss of aroma in the tea liquor.