Jun porcelain originated in the Tang Dynasty and flourished during the Song Dynasty. It is one of China's five famous ancient porcelains and is often said to be “priceless compared to gold.” Renowned for its magical kiln transformations, it boasts a rich variety of colors, a stunning beauty, and infinite changes, making it a treasure among Chinese ceramics.

Wang Zengqi once wrote, “The Jun porcelain is a wonder in the world, unmatched by any glaze. As red as a rain-soaked hibiscus, as green as the sky after a cloud clears. Eggplant purple like grapes, speckled like fish roe on ice. Who could craft such wonders? Divine skill through human effort.”

In this article, we will provide a brief introduction to the materials used in the production of Jun porcelain and some tips for shaping the clay.

-Main Raw Materials for Producing Jun Porcelain-

The primary raw materials used in the production of Jun porcelain include: Qingjian, black fetal white soil, white fetal white soil, sandstone, feldspar, and black hairy soil.

The glaze materials mainly consist of feldspar, calcite, agate, talc, copper ore, iron ore, etc.

All these raw materials are mined from the mountains around Shenhoushan. Initially large stones, they are placed in a material pool where they naturally soften over time due to exposure to wind, sun, and rain. Then, they are ground in a ball mill until they turn into mud, which is refined before becoming the clay we use.

-Points to Note When Shaping the Clay-

Firstly, shaping the clay requires two essential factors:

Peace of mind, accurate vision, and steady hands.

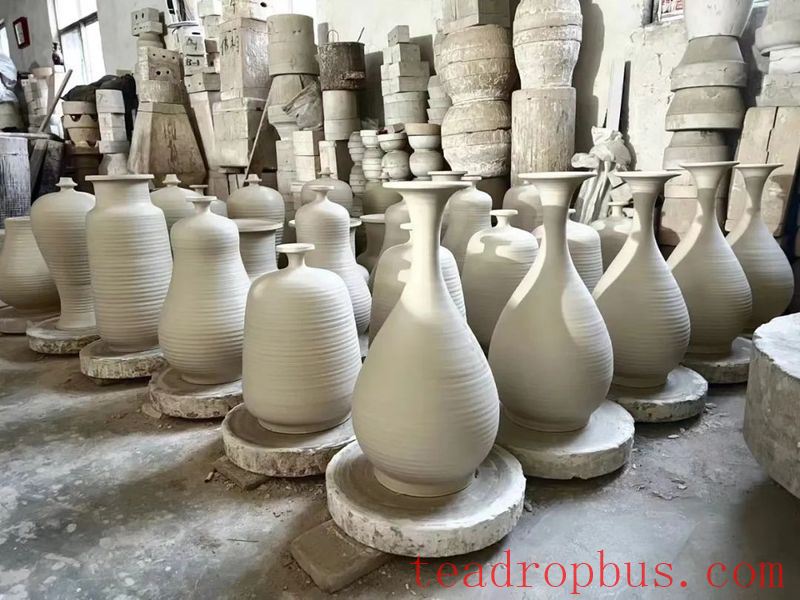

Secondly, before shaping the clay, you must have a clear idea of what object you want to make and how to apply the techniques. These are things that must be carefully considered beforehand! Once these preparations are made, you can begin shaping the clay.

The first step in shaping the clay is centering the clay head, which determines whether or not the shape can be successfully formed.

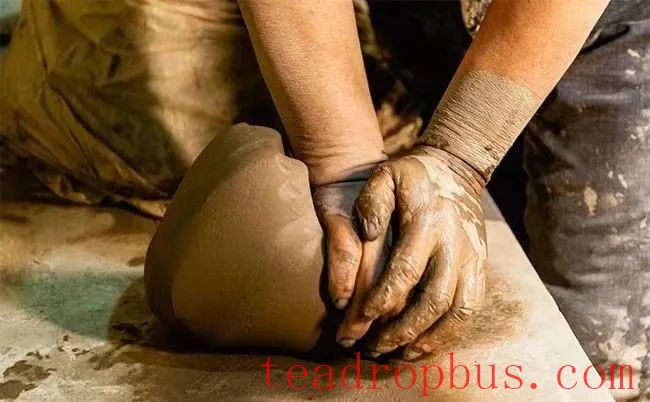

Centering the clay head involves throwing the kneaded clay onto the wheel and using both hands to center it. The term “centering” means aligning the clay with the same center as the wheel. This alignment is necessary to proceed to the next step.

Through repeated raising and pressing, impurities and air bubbles in the clay are further removed, and the clay becomes more malleable.

Then the shaping process begins. Throughout this process, stability is key, and the speed should be moderate. According to the contours of the object envisioned in your mind, translate those thoughts into hand movements to skillfully manipulate the clay.

“One Color into the Kiln, Ten Thousand Colors Out.” After firing, Jun porcelain transforms in diverse ways with rich colors. Each firing fills us with anticipation, revealing the marvels of nature's creation.