From the processing of fresh leaves into finished tea, to distribution in the market for sale, and finally purchase by consumers for home use, it often takes several months or even longer. During this period, a series of complex physical and chemical changes occur in the tea, affecting its quality to varying degrees. The primary influencing factors include moisture content, temperature, oxygen, light conditions, and packaging materials.

1. Moisture Content

When the moisture content of tea is 3% to 5%, it can effectively prevent oxidation and deterioration. However, when the moisture content exceeds 12%, mold growth occurs, producing stale flavors that significantly affect the tea's quality. It is considered ideal for storage humidity to be less than 60%. If the air is too humid, dry tea will absorb moisture from the air, leading to quality deterioration. Studies on different moisture contents of baked green tea have shown that the higher the moisture content, the faster the deterioration of tea quality. The quality of black tea decreases with increasing moisture content. Research on the initial moisture content of White Tea during storage has found that within a 12-month storage period, the higher the initial moisture content of white tea, the greater the decline in amino acid and polyphenol content. The international standard for moisture content in white tea is 8.5%, but in actual storage, a lower moisture content is often required, such as Fuding white tea, which should be controlled below 6% and stored in a dry environment. As dark tea is fully fermented, it requires suitable humidity to accelerate its aging process; for example, Pu'er tea at 9% moisture content is most conducive to the development of good quality characteristics. These research results indicate that different types and processing methods of tea have different requirements for moisture content during storage, and the most suitable moisture content for storage should be selected based on specific samples. Controlling the moisture content at a low level and storing the tea in a dry environment can better extend its shelf life for most teas.

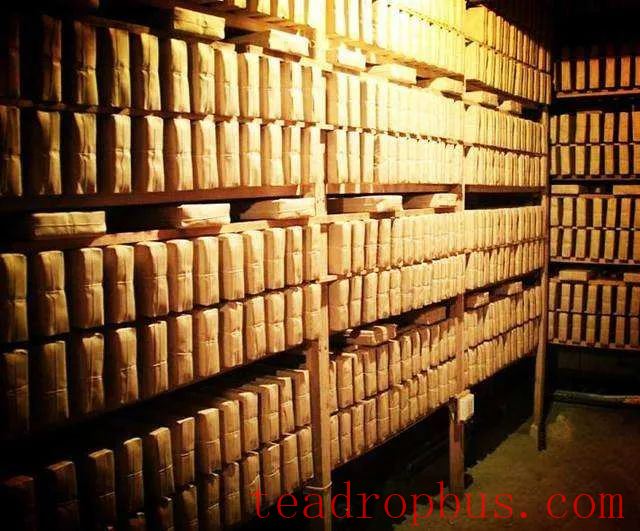

Standardized white tea storage cellar (Image courtesy of Liu Miao Company)

2. Temperature

Low or constant temperatures can slow down the quality change of tea. There are significant differences in the degree of quality deterioration of green tea stored at different temperatures. The lower the storage temperature, the more quality components are retained, and the better the sensory quality. Therefore, many studies consider refrigeration to be the best method for storing green tea. Green tea stored at -80°C and -20°C retains freshness in terms of color, aroma, and taste, while green tea stored at 4°C and room temperature shows a significant decrease in quality. After half a year of storage, the content of polyphenols in stir-fried green tea decreased by 20% under low-temperature (below 8°C) treatment, while polyphenol content dropped by 28% in room temperature-treated tea. Studies on the effect of temperature on the quality of black tea during storage show that low-temperature (0-10°C) treatment can effectively slow down the deterioration of black tea; constant temperature (26°C) treatment also has some slowing effect; however, normal temperature (12-25°C) treatment has the greatest impact on the quality of black tea. When tea is taken out from a low-temperature storage environment, the temperature difference should be eliminated first, which has a significant effect on maintaining the quality of Longjing tea and lightly fermented Tieguanyin. However, Oolong tea is not necessarily better stored at lower temperatures, as 5°C refrigerated storage is better than -18°C (freezing) and room temperature. The optimal temperature for white tea storage is 10-33°C; temperatures that are too high or too low are not conducive to storage. Unlike other teas, white tea is not suitable for refrigerator storage, as low temperatures can affect the conversion of biochemical components, hindering the formation of EPSF-type components. Therefore, when storing at low temperatures, one must consider the differences in tea type and external environmental conditions that affect the quality of stored tea.

3. Oxygen

When the oxygen content in the tea packaging container is controlled below 0.1%, the flavor and aroma of the tea can be well maintained. However, when the oxygen content exceeds 5%, the tea gradually deteriorates. Green tea, black tea, and Yellow Tea, which are easily oxidized, are typically packaged with nitrogen gas to delay quality changes. Compared to aerobic conditions, chlorophyll, polyphenols, and vitamin C content decrease more during storage under oxygen-free conditions, indicating that oxygen removal can slow down the quality change of tea. Unlike other teas, dark tea requires moderate oxygen during storage to accelerate the transformation of its internal components. Therefore, bamboo baskets or kraft paper are usually used for packaging, and the tea is stored in a ventilated environment. Additionally, low-oxygen storage can inhibit the impact of high moisture content on tea quality, demonstrating the critical role of oxygen removal in maintaining tea quality.

4. Light Conditions

Light can promote the degradation of pigments and the oxidation of lipid substances in tea, accelerating its quality change and aging. Tea pigments are very sensitive to light, especially the yellow-green chlorophyll b, which readily degrades under light, causing the dry tea to lose its brightness. Results of changes in biochemical components of green tea stored at room temperature under light-avoiding and light-exposed conditions show that after two months of storage, there is no significant change in the quality of green tea stored in the dark, whereas the color of green tea stored under light gradually turns yellow and develops stale flavors. This may be due to unsaturated fatty acids degrading into low-molecular aldehydes, ketones, and alcohols, producing unpleasant volatile gases that dissipate the original fresh and refreshing aroma. Light causes large volatilization of lipids and condensation of Pectin substances in black tea, reducing its aroma. After five hours of exposure to light, the content of phenolic substances, amino acids, and Caffeine in the tea decreased by 6%, 9%, and 6%, respectively, compared to conditions avoiding light. Therefore, storing tea in the dark can effectively slow down the transformation rate of internal substances, thus delaying quality change. This is why tea packaging materials need to have good light-blocking properties, as required in the market.

5. Packaging Materials

In general, tea packaging requires moisture-proofing, oxygen barrier, light-blocking, and sealing, with lower oxygen and moisture permeability being preferable. Compared to ordinary packaging materials, newly developed nanomaterial packaging for green tea has lower oxygen and moisture permeability, effectively improving the freshness and quality of green tea. High-density polyethylene, polypropylene, polyester, and other materials combined with low-density polyethylene film into double or triple-layer composite materials are ideal for tea preservation packaging. Among three different packaging materials, aluminum-coated composite film (CPP aluminum-coated/PE) provides the best preservation effect, followed by aluminum-plastic film (PET/Al/PE), with low-density polyethylene (LDPE) being the least effective. However, tea is not typically packaged using a single material. In practical storage and preservation processes, two or more materials are often combined to achieve the best preservation effect.

Aluminum-coated composite film packaging bag

In summary, different types of tea have different requirements for storage conditions. Suitable storage conditions and packaging materials should be chosen according to their inherent qualities and market sales needs to stabilize or improve tea quality and extend the storage period.

(To be continued)

This excerpt is from “China Tea,” Issue 12, 2025, pp. 1-10, “Research Progress in Tea Storage Chemistry and Storage Technology.” Authors: Gao Jianjian, Chen Dan, Peng Jiaxuan, Wang Zhe, Wu Wenliang, Lin Zhi,