Dark Tea is one of the six major types of Chinese Tea and is widely popular among consumers both domestically and internationally for its weight-loss, lipid-lowering, and digestive-regulating properties. The raw materials used in making dark tea (such as Qing brick and Fu brick teas) are typically mature leaves with a high degree of development, such as those with four or five leaves per bud. These materials tend to be coarse in appearance, leading to less appealing aesthetics both in the dry tea form and after brewing. This restricts the diverse consumer demands. Studies have shown that there is an inverse relationship between the maturity grade of fresh leaf materials and the quality of the dry tea's appearance, with higher tenderness levels being more conducive to shaping the appearance of dry tea. In traditional dark Tea processing, mature raw materials often contain high levels of fluoride, which can pose drinking safety concerns and hinder the development of dark tea.

The research group previously studied the relationship between different varieties of green tea raw materials and dark tea quality. After piling fermentation of 13 varieties of green tea raw materials, it was found that dark tea made from Echa No.10 had a brownish-red appearance, orange-yellow liquor, a pronounced aged aroma, and a sweet, mellow taste, with overall excellent quality. Dark teas available on the market are generally processed from raw materials with higher maturity, while pure bud dark tea has not yet been seen. For the first time, the research group used single buds of Echa No.10 as experimental material, employing a three-factor (moisture content of the wet tea, piling temperature, and humidity) and three-level orthogonal experimental method to optimize the dark tea piling process, aiming to provide theoretical support for the development of high-quality dark tea products.

01

Materials and Methods

1. Materials and Equipment

In September 2015, sun-dried green tea (fresh leaf material of Echa No.10, single buds) was purchased from Wutai Changchen Tea Industry Co., Ltd. in Xuan'en County, Hubei Province.

The processing equipment included a DHG-9246A electric heating constant temperature air circulation drying oven (Shanghai Jinghong Experimental Equipment Co., Ltd.) and an RXZ-328Z artificial climate chamber (Ningbo Jiangnan Instrument Factory). The testing instruments used were a WSC-S colorimeter (Shanghai Precision Scientific Instrument Co., Ltd.), an AUY220 electronic analytical balance (Shimadzu, Japan), a 1260 Infinity high-performance liquid chromatograph (Agilent, USA), and a 722N visible spectrophotometer (Shanghai Jinghua Scientific Instrument Co., Ltd.).

2. Processing Method

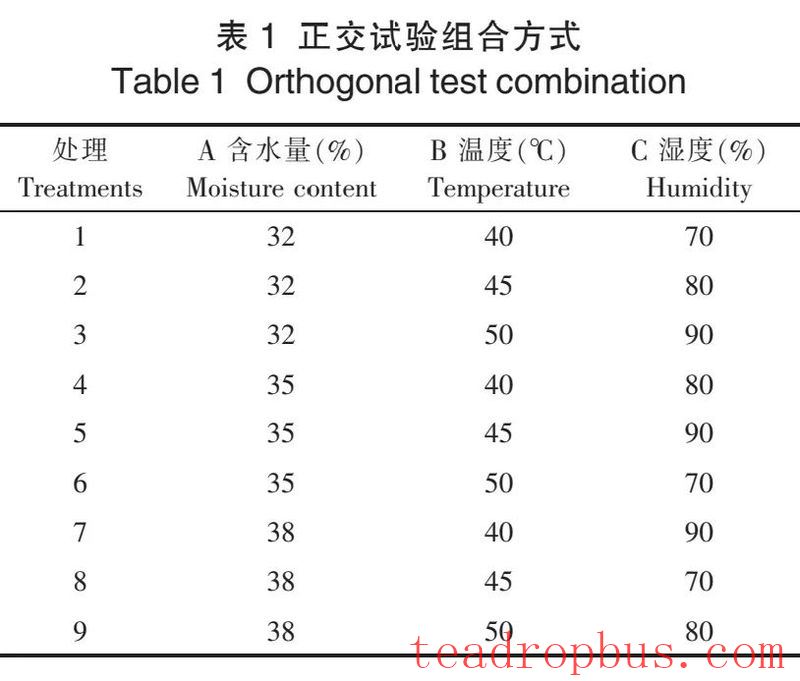

The experiment set three factors at three levels: moisture content of the wet tea (32%, 35%, and 38%), piling temperature (40°C, 45°C, and 50°C), and humidity (70%, 80%, and 90%). An orthogonal experiment was conducted, with treatment combinations detailed in Table 1. First, the sun-dried green tea raw materials were mixed evenly. Then, 2.5 kg of the mixture was taken for each treatment, and water was sprayed to adjust the moisture content to the predetermined level. Next, the tea with absorbed moisture was placed in a tea basket and covered with a damp cloth. Finally, the tea baskets were placed in the RXZ-328Z artificial climate chamber for piling fermentation, with the tea blocks being loosened and turned every three days. Sampling and evaluation occurred around the 12th day to determine the appropriate piling duration, which was ultimately confirmed to be 13 days for the single bud raw material. After piling, the tea was dried at 105°C for 1 hour. After cooling for 1 hour, the tea was re-dried at 95°C until the moisture content reached approximately 6%.

3. Analytical Methods

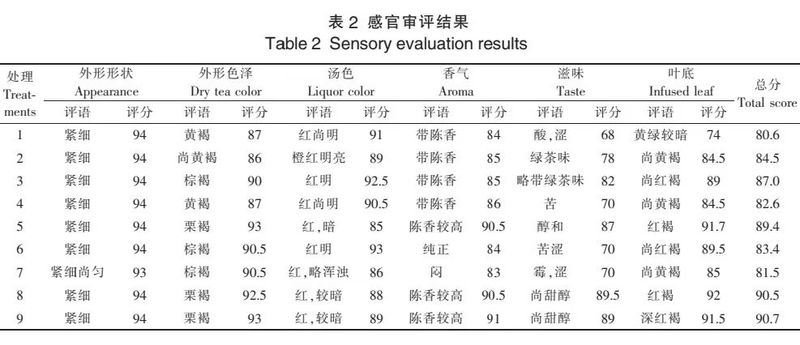

The sensory evaluation method specified in GB/T 23776-2025 was followed, with a full score of 100. Since the experiment used single bud dark tea, the appearance was divided into shape and color, and weighted scores were assigned according to shape (10%), color (10%), liquor color (15%), aroma (25%), taste (30%), and infused leaves (10%) to calculate the total quality score. Moisture content determination in the tea was conducted using the 120°C rapid detection method. Chemical component analysis: soluble Sugar content was determined using the anthrone-sulfuric acid colorimetric method; tea polyphenol content was determined according to the Folin-phenol colorimetric method specified in GB/T 8313-2025; free amino acid content was determined according to the ninhydrin colorimetric method specified in GB/T 8314-2013; water extractable matter content was determined according to the vacuum filtration method specified in GB/T 8305-2013; catechin components were analyzed using high-performance liquid chromatography. The contents of theaflavins, thearubigins, and theaflavins were detected using an organic reagent extraction-systematic analysis method. Color analysis of the dry tea and tea liquor was performed using a colorimeter.

4. Data Processing

Data results are expressed as mean ± SD, with experiments repeated three times. Data analysis was conducted using Excel and SPSS Statistics 20, with significance considered at p < 0.05.

02

Results and Analysis

1. Sensory Evaluation Results

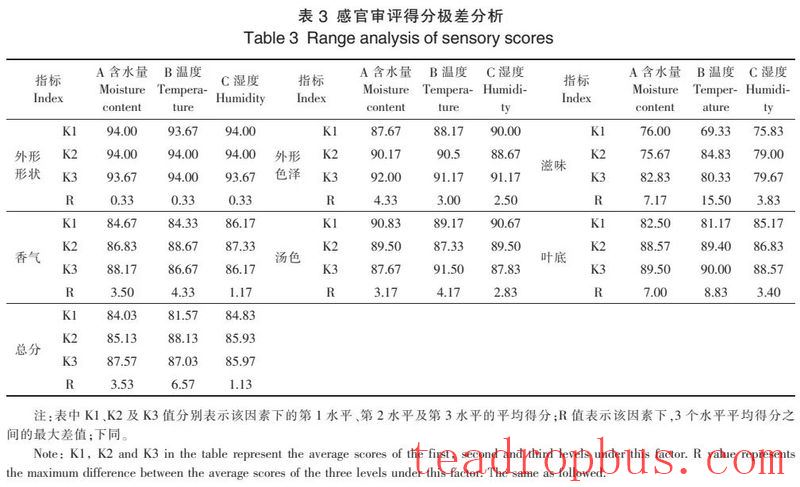

The sensory evaluation results of the various samples are shown in Table 2. Sample No.9 and No.5 received the highest scores for appearance color (93 points each). The influence of piling fermentation conditions on the appearance color score of single bud dark tea was greatest for moisture content, followed by temperature and then humidity. The Echa No.10 single bud raw material used in the study is relatively tender, resulting in a tightly shaped, aesthetically pleasing dry tea. Variance analysis showed no significant effect of the three factors on the shape score. Regarding liquor color, treatment No.6 had the best liquor color (bright red, 93 points), followed by No.3 (bright red, 92.5 points). In terms of aroma, sample No.9 had the highest aged aroma score (91 points), followed by No.5 and No.8. Concerning taste, treatment No.8 had the most sweet and mellow flavor (89.5), with No.9 scoring 89 points. For infused leaves, treatment No.8 scored the highest (92 points), followed by No.5 (91.7 points) and No.9 (91.5 points).

Variance analysis (Table 3) shows that the influence of piling conditions on liquor color, aroma, taste, infused leaves score, and total score was greatest for temperature, followed by moisture content and humidity. The parameter combination with the highest score was A3B2C3, which corresponds to a moisture content of 38%, piling temperature of 45°C, and humidity of 90%.

2. Color Difference Analysis

The color difference parameters of the dry tea of the various samples and the variance analysis results are shown in Tables 4 and 5. The effects of different orthogonal combination conditions on L*, a*, b*, and b*/a* values of the dry tea varied. The influence of piling fermentation conditions on the L* value of the dry tea was greatest for moisture content, followed by temperature and then humidity. The brightness of the dark tea increased with increasing moisture content of the wet tea. Among the treatments, No.2 had the highest L* value (brightness) (41.43 ± 0.02), while No.8 had the lowest (28.16 ± 0.02