Black Tea, renowned for its unique quality, is highly favored by consumers and accounts for approximately 80% of global Tea sales. The quality of black tea can vary due to differences in raw material origin, tea plant variety, and processing methods, leading to distinct regional characteristics in flavor. Yunnan large-leaf black tea, also known as Dian Hong, is made from fresh leaves of the Yunnan large-leaf tea plant. It undergoes withering, rolling, fermentation, and drying processes, resulting in a highly aromatic black tea that is appreciated for its “red liquor and red leaves, high fragrance, bright color, fresh and refreshing taste, and strong flavor.”

The biochemical and aroma components are key factors determining the quality of black tea. Many factors influence these components, including tea plant variety, cultivation environment, agronomic practices, processing methods, and storage conditions. Processing is a critical step in the formation of tea's aroma compounds. As processing technologies improve, changes occur in the aroma quality and functional components of black tea. Peng Yun et al. analyzed the aroma profiles of black teas from different origins using SPME/GC-MS and found variations in their aroma components. Lei Dengdeng et al. studied the quality characteristics of Qimen black tea from different regions and discovered differences in biochemical and aroma qualities. Yang Caixia et al. investigated the changes in aroma and chemical components of finished Dian Hong black tea under different baking conditions and found that baking at 70°C and 90°C for 1 to 2.5 hours could enhance the tea's aroma. Lin Yanping et al. explored the effects of different withering methods on the quality of Wuyi black tea “Jin Jun Mei,” finding differences between natural withering and hot air withering. Zhou Qinyu et al. examined the impact of piling after preliminary drying on the quality of summer black tea and found that piling for 3 hours after preliminary drying significantly improved the tea's quality compared to traditional processing methods. Researchers studying the aroma compositions of Zhengshan Xiaozhong and smoked Zhengshan Xiaozhong black teas discovered unique volatile compounds such as guaiacol, 4-methylguaiacol, and 4-ethylguaiacol in the smoked variety.

Previous studies have investigated the effects of different regions, tea plant varieties, and processing methods on the quality of black tea. However, there has been no report on the production of smoked large-leaf black tea using local plants like the Simao pine in a unique climate, and subsequent analysis of its quality characteristics. Therefore, this study draws inspiration from the processing method of smoked Zhengshan Xiaozhong, using one bud and two leaves of the Yunnan large-leaf tea plant. On the basis of traditional black Tea processing, smoke curing with Simao pine was introduced into the process. The effects of smoke curing on sensory quality, biochemical quality, and aroma quality were explored to provide a theoretical foundation for the processing of large-leaf black tea.

01

Materials and Methods

1. Materials and Instruments

The materials used were collected from Yingpanshan in Pu'er City, Yunnan Province, at an altitude of 1,700 meters. The variety used was a group cultivar, and the picking standard was one bud and two leaves. The samples were picked in April 2025 and processed using the Gongfu black tea processing technology, which includes fresh leaves, withering, rolling, fermentation, preliminary drying, and final drying.

2. Experimental Methods

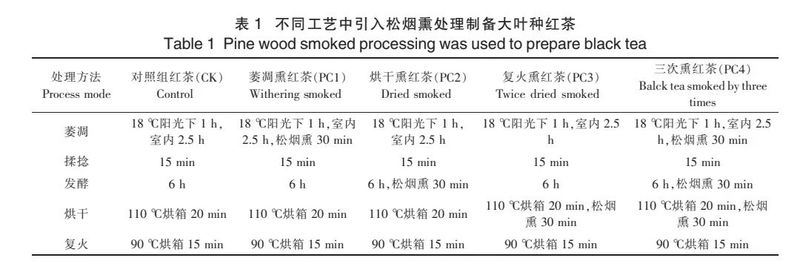

Smoke curing was conducted during three stages of black tea processing: withering, drying, and re-drying. Control, withered-smoked, dried-smoked, and re-dried-smoked black teas were prepared. Each treatment was replicated three times, with specific parameters shown in Table 1. The smoke curing method involved placing charcoal at the bottom without open flames and placing a bamboo sieve on a tripod, with the tea leaves placed on the sieve. A thermometer was used to control the temperature during smoke curing.

02

Results and Analysis

1. Sensory Evaluation and Analysis of Smoked Large-Leaf Black Tea

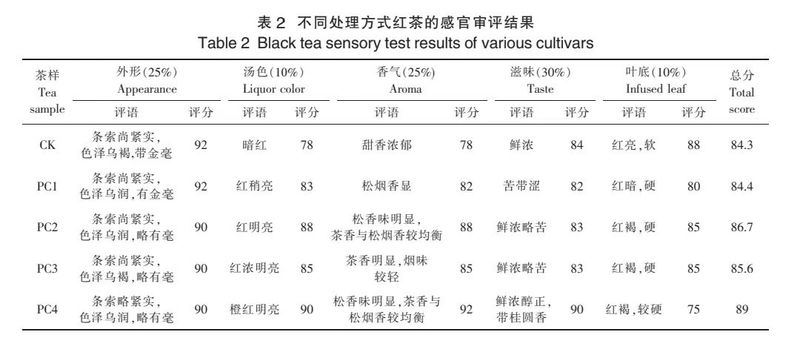

From Table 2, it can be seen that the sensory evaluation scores of the smoke-cured black teas were: three-time smoke (PC4) > dried smoke (PC2) > re-dried smoke (PC3) > withered smoke (PC1) > control (CK). The tea leaves absorbed the aroma of the pine at different stages of processing, enhancing the tea's astringency and highlighting its strong, concentrated, and fresh characteristics. The sensory scores of all treatments were higher than those of the control. After smoke curing, the dry tea exhibited a more lustrous appearance with features such as dark black and glossy black. During withering, the fresh leaves had a higher water content and were in a relaxed state, absorbing the smoky flavor prominently. During the drying stage, the tea absorbed less of the pine aroma, resulting in a smoky dry tea with a fresh and slightly bitter taste. Under the three-time smoke treatment, the tea absorbed a purer pine aroma, imparting a fresh, slightly bitter taste with a Osmanthus aroma. The quality was consistently stable across the three parallel experiments at each stage.

2. Biochemical Component Analysis of Smoked Large-Leaf Black Tea

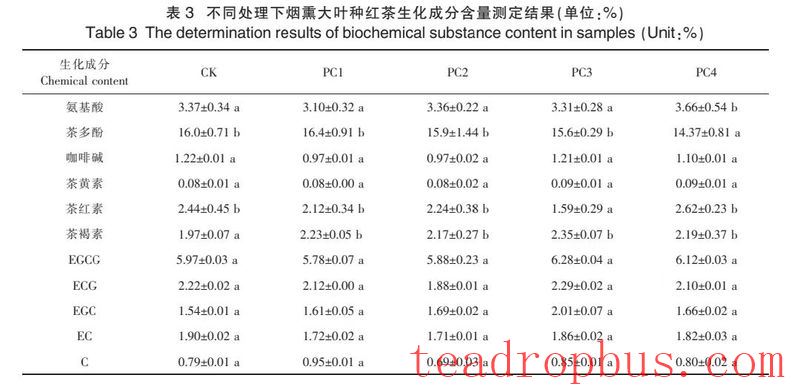

As shown in Table 3, the amino acid content range of the samples was 3.10% to 3.66%, with the highest level in the three-time smoke (PC4) and the lowest in the withered smoke (PC1). There was not much change in the content of the dried smoke (PC2) and the control (CK). The tea polyphenol content was highest in the withered smoke (PC1), while the control (CK), dried smoke (PC2), and re-dried smoke (PC3) all had significantly higher contents than the three-time smoke (PC4). There were no significant differences in caffeine content among the different treatments.

As shown in Table 3, the Theaflavin content range of the samples was 0.08% to 0.091%, with the content remaining relatively stable across different treatments, showing no significant differences. The thearubigin content of the three-time smoke was 1.65 times that of the re-dried smoke, and the control was 1.53 times that of the re-dried smoke. The theabrownin content of the re-dried smoke was 1.19 times that of the control. There were no significant differences in the theabrownin content between the withered smoke, dried smoke, and three-time smoke. Due to excessive fermentation of the experimental samples, the theaflavin content was low, and the overall color of the liquor was dark. The theabrownin content of all treated samples was higher than that of the control.

As shown in Table 3, the EGCG content range of the samples was 5.78% to 6.28%, the ECG content range was 1.88% to 2.22%, the EGC content range was 1.54% to 2.01%, and the EC content range was 1.71% to 1.90%. The C value range of the samples was 0.69% to 0.95%, with no significant differences in catechin content among different treatments.

3. Aroma Compound Analysis of Smoked Large-Leaf Black Tea

As shown in Table 4, a total of 50 aroma compounds were detected in the samples. The number of compounds detected in each group was as follows: 42 in the control, 32 in the withered smoke, 41 in the dried smoke, 42 in the re-dried smoke, and 38 in the three-time smoke. The aroma composition included alcohols, aldehydes, esters, ketones, phenols, acids, hydrocarbons, etc.,