The production process of Puer raw Tea includes: picking —— withering —— fixation —— rolling —— sun-drying —— steaming and pressing —— air-drying —— packaging and storage for transportation.

1. Fresh Leaf Picking

The tea trees can be divided into large and small trees. Picking from small trees is simple and convenient, while picking from large trees requires the tea farmers to climb onto the trees, which is one reason why large tree tea commands a higher price due to the difficulty in picking leading to lower yields. Some large trees can be picked using ladders, but in areas where ladders cannot be used, it becomes quite dangerous.

2. Withering

After the fresh leaves are picked, they need to be spread out thinly to promote the evaporation of moisture and soften the leaves, making them suitable for fixation.

3. Fixation (Machine and Handmade)

Puer tea fixation can be done by machine or by hand. Machine fixation allows for good temperature control and mass production, resulting in a consistent taste. Manual fixation, on the other hand, is less stable as each master has different experience, leading to variations in taste. Traditional handmade fixation involves a pot temperature of over 150 degrees Celsius, with the leaves being placed in the pot for more than five minutes.

4. Rolling

In simple terms, rolling is the process of shaping the tea leaves. It requires appropriate force to prevent fragile leaves from breaking at folded points. Rolled leaves that have been stacked need to be rolled tightly into strips. At the beginning of the rolling process, light rolling is used to increase the resilience of the leaves and the permeability of cell membranes, making them soft and allowing the leaf substance to flow out, gradually forming tight strips.

5. Sun-Drying Naturally

Drying is the final step in the production of raw tea. Puer tea uses sun-drying as its drying method. Currently, in the ancient tea regions, tea farmers dry their tea naturally in the sun. During the Spring Tea season, if tea enthusiasts visit the tea mountains, they will see tea leaves spread out in courtyards, along roadsides, and even on rooftops. Drying naturally in sunlight is currently the best drying method, preserving the authentic flavor and rich internal components of Puer tea.

6. Sifting

Puer tea undergoes sifting to grade it into categories such as Imperial, Grade 1, Grade 2, etc. Non-tea contaminants like stones, husks, etc., are removed, as well as old stems, flowers, fruits, and other tea-related impurities.

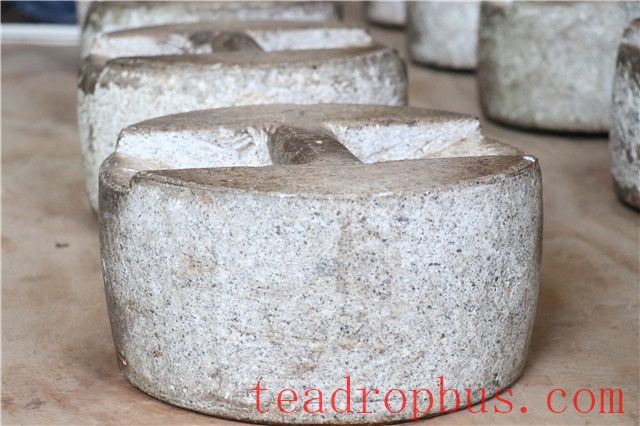

7. Steaming and Pressing

This is similar to the steaming process for raw tea. The temperature, time, and pressure during steaming and pressing have an absolute impact on the aroma and taste of the tea. This is also the key factor behind the differences between teas from large factories and smaller ones, even when the tea regions and grades are the same.

8. Packaging and Storage for Transportation —— must meet requirements for sturdiness, cleanliness, moisture-proofing, and attractiveness. Food-grade packaging materials must be used, along with a series of accompanying instructions tailored to Puer tea. After packaging, the tea must be stored in dry warehouses to prevent any adverse effects that could spoil the quality of the Puer tea.