Black Tea processing requires withering, rolling, fermentation, and drying to form the characteristic red liquor and red leaf quality features of black Tea, among which withering is an important process in the formation of black tea quality.

In traditional black Tea processing, the withering process mainly uses indoor natural withering, and the withering time usually takes 8 to 12 hours; due to the complexity and continuity of the formation of black tea quality and processing technology, subsequent rolling, fermentation, and drying processes also typically require a considerable amount of time, leading to issues such as low processing efficiency and high labor intensity in black tea processing.

Studies have shown that hot air withering can improve the quality of black tea, and there are differences in the quality of black tea at different hot air withering temperatures; therefore, further elucidating the impact of different temperature hot air withering processes on black tea quality is of significant importance for the application of hot air withering technology in industrialized black tea processing.

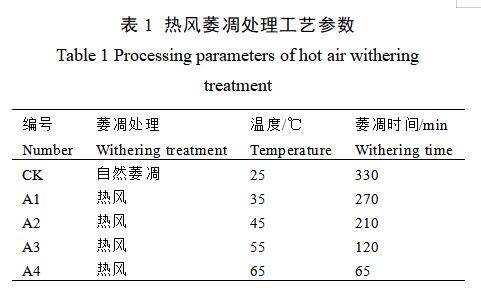

This issue uses 25°C indoor spreading natural withering as a control and replaces the traditional indoor natural withering process with four hot air withering processes at 35°C, 45°C, 55°C, and 65°C in traditional black tea processing. It systematically analyzes and compares the effects of different temperature hot air withering on the quality of withered leaves and finished tea from the perspectives of sensory quality, taste, and aroma quality components, aiming to provide scientific evidence for the processing of high-quality black tea.

Results and Analysis

1. Sensory Quality Analysis of Finished Black Tea

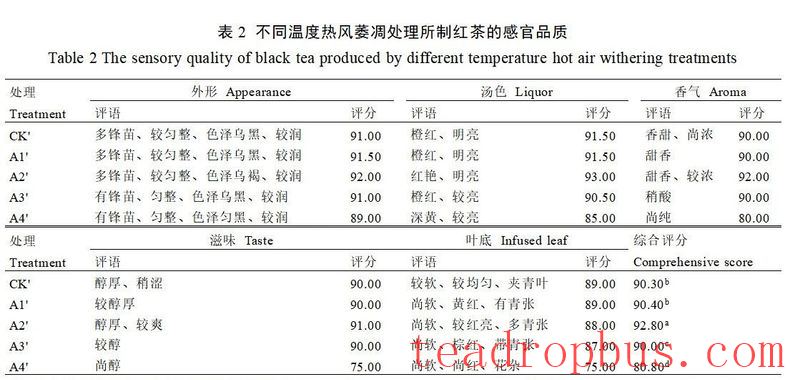

Appearance: The appearance of the finished black tea samples produced using hot air withering processes mostly has golden tips and is relatively uniform; Group A4′ (65°C hot air withering for 65 minutes) has a uniformly dark color and is relatively lustrous, scoring the lowest for dry tea appearance.

Inner Quality: There are more noticeable differences in inner quality scores, among which Group A2′ (45°C hot air withering for 210 minutes) has a bright red liquor with a strong sweet fragrance, achieving the highest overall score of 92.8 points; Group A4′ (65°C hot air withering for 65 minutes) has a deep yellow liquor, a pure aroma with a heap odor, a somewhat mellow taste, and a mixed leaf bottom, scoring the lowest overall score of 80.8 points (Table 2). The main reason may be that when hot air withering is performed at appropriate temperatures, some oxidation and reduction reactions occur at accelerated rates, promoting the production of key taste quality components; however, in Groups A3′ and A4′, the higher hot air withering temperatures caused some taste quality components to undergo transformation or destruction.

Note: Different lowercase letters indicate significant differences between treatments (P

2. Analysis of Taste Quality Components in Finished Tea

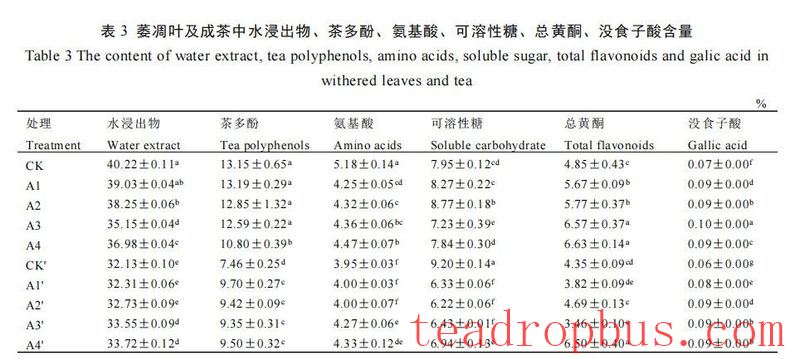

Compared with the traditional 25°C indoor spreading natural withering process, the content of water-soluble extracts, tea polyphenols, free amino acids, and gallic acid in the finished tea samples treated with hot air withering processes all increased to varying degrees, while the content of soluble sugars decreased (Table 3). It is speculated that as the blower temperature rises, the activity of related hydrolases within the leaf cells increases, causing some large molecular substances to be hydrolyzed into small molecular substances for participation in subsequent material transformations.

Note: Different lowercase letters indicate significant differences between treatments (P

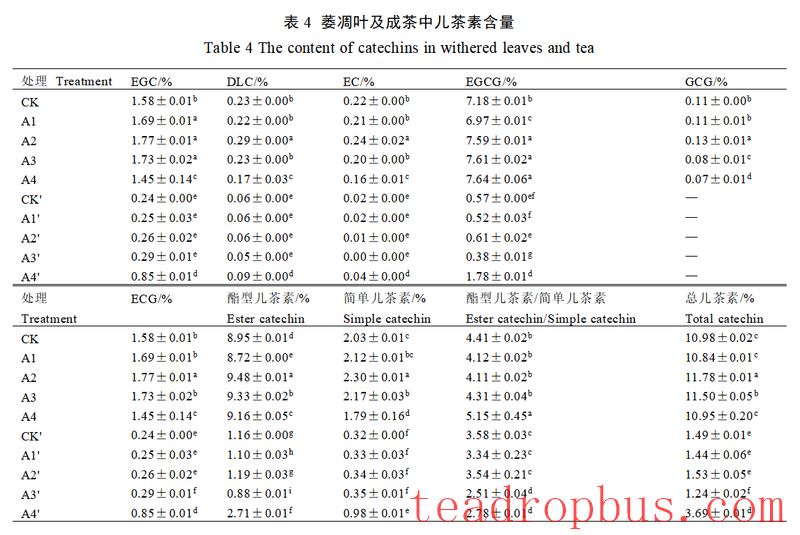

The content of ester-type catechins in the finished tea samples processed through traditional 25°C natural withering is slightly higher (Table 4), and these ester-type catechins have a bitter and astringent taste, consistent with the slightly astringent taste in the sensory evaluation. Combined with the slightly lower detection results of theaflavins in the finished tea samples processed at 25°C, it is speculated that when the withering temperature is lower, surface water loss is impeded, and biochemical reactions within the leaf are not intense, hindering the conversion of catechins to theaflavins.

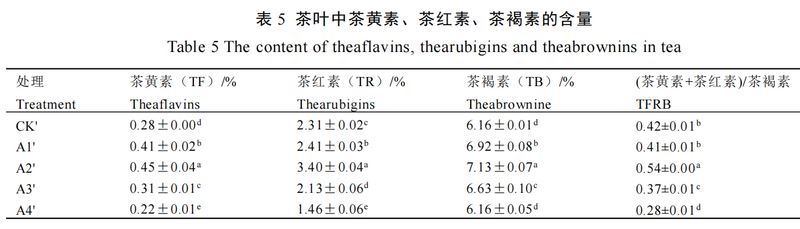

The content of theaflavins and thearubigins in the tea samples processed by Group A2′ (45°C hot air withering for 210 minutes) is the highest (Table 5), consistent with the bright red liquor result in the sensory evaluation. This may be because during hot air withering, epicatechin is preferentially oxidized to form o-quinones, which then undergo condensation reactions to form theaflavins and thearubigins.

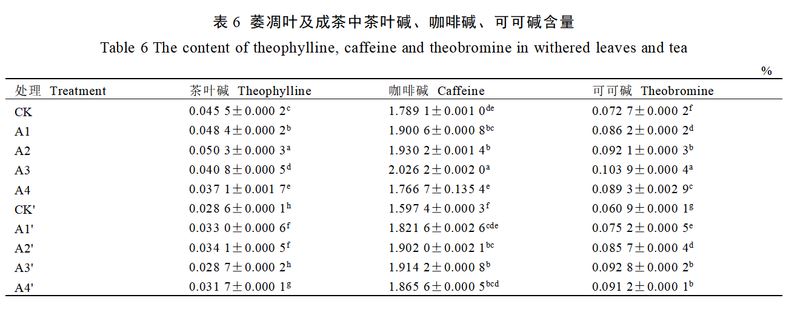

The content of alkaloids in finished tea increases with the rise in withering treatment temperature (Table 6). Caffeine has a bitter and astringent taste, affecting taste quality; therefore, the temperature should not be too high during hot air withering.

Group A4′ (65°C hot air withering for 65 minutes) shows significant differences compared to the other hot air withering treatment groups and has poor sensory evaluation results. It is speculated that when the hot air temperature reaches 65°C, the leaf temperature is high, and the leaf moisture evaporates too quickly. Although the enzyme activity is rapidly activated, it remains active for a shorter period, which is unfavorable for the oxidation of catechins, leading to damage to the cell semi-permeable membrane and its molecular structure, resulting in insufficient substance transformation and excessive residual amounts of catechins, especially ester-type catechins, affecting the quality of the tea.

Through aroma quality analysis, a total of 56 volatile components were identified. Linalool, an important alcohol aroma component in black tea, showed a significantly increased relative content at 45°C hot air withering (P