For newcomers to the world of purple clay Teapots, the variety of techniques can often be overwhelming. However, mastering the following common terms will ensure you never appear uninformed again.

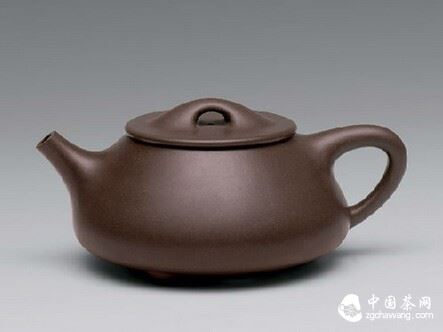

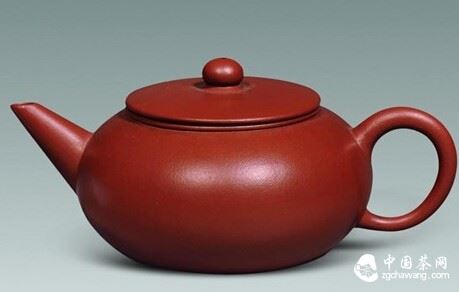

【Smooth Teapot】

Smooth teapots are divided into round and square shapes. Round teapots emphasize “roundness, stability, uniformity, and correctness,” with a requirement for “softness containing firmness.” Square teapots require “squareness containing roundness,” with lines and surfaces being firm and flat, and contours clearly defined.

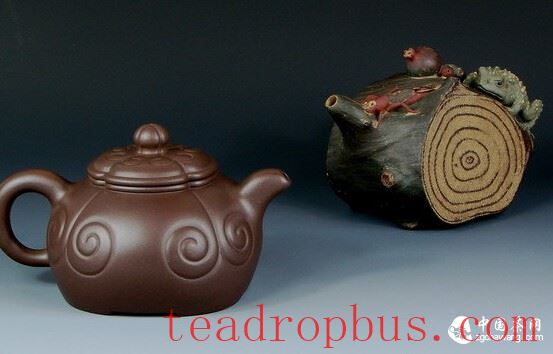

【Floral Teapot】

Floral teapots primarily imitate natural forms such as animals, plants, and everyday objects, adding a unique touch of charm. The term “floral ware” generally refers to sculptural vessels and vessels adorned with bas-reliefs or half-round sculptures.

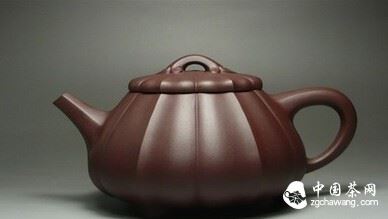

【Veined Teapot】

Veined teapots create a sense of beauty through the interweaving and combination of lines. The basic requirement is that the veins change in depth naturally according to the shape of the vessel, with clear lines and textures.

【Patina】

“Patina” essentially refers to “luster,” specifically the sheen on the surface of an antique. The patina of a Purple Clay Teapot is a natural luster that develops over a long period of time. This luster is understated and warm, not flashy, distinguishing it from the bright shine of a brand new purple clay teapot.

【Injection Molding】

Injection molding utilizes the water-absorbing properties of plaster by heating wax-containing slurry and pouring it into a plaster mold. After cooling, the mold is removed to obtain the teapot body. Mouths, handles, and spouts are added, and the wax is removed before firing. The clay used for injection molding must be at least 200 mesh and contains a lot of glass water, which reduces the teapot's breathability. Injection molding is particularly suitable for mass production and has lower costs. An individual can produce 300-500 teapots using this method in a single day.

【Handmade】

The general process of handmade teapot making includes: 1. Rolling clay sheets; 2. Forming the body; 3. Shaping the body; 4. Shaping the spout, lid knob, and handle; 5. Attaching the spout, lid knob, and handle; 6. Making the lid; 7. Cutting the mouth opening; 8. Smoothing and finishing; 9. Stamping the maker's mark. Since handmade teapot makers must not only master the skills of shaping clay but also utilize the characteristics of the purple clay material to create an artistic atmosphere, handmade teapots are not only functional Tea wares and decorative crafts but also have artistic and collectible value.

【Semi-handmade】

Semi-handmade teapots generally contain some handcrafted elements. Some may have the spout, handle, and lid made by hand while the body is molded. Others might have the body formed by hand with other parts made using molds. “Semi-handmade” can also refer to pieces where the final shaping is done using a model mold after initial handcrafting. If the use of molds does not exceed a certain amount during the entire process, the teapot can still be called “semi-handmade.”

【Mesh Size】

Mesh size typically refers to the coarseness or fineness of the clay. Generally, anything below 60 mesh is considered coarse, while anything above is fine. The higher the mesh number, the finer the clay. Conversely, the graininess of the clay will be more pronounced.

【Aging of Purple Clay】

The aging of clay, also known as maturation, was traditionally referred to as soil nurturing, and is also commonly known as storing and conditioning the clay. It is one of the processing steps for purple clay ore. Typically, after mining, the purple clay ore needs to be sun-dried, crushed, weathered, ground, sieved, mixed with water, and formed into wet clay blocks about six inches wide and one foot long. These blocks are then stored in a dark, damp place away from sunlight and air to maintain a certain temperature and humidity, improving the clay's properties.

After slowly aging, the wet clay becomes “aged clay.” Its moisture is evenly distributed, facilitating the oxidation of the body and allowing organic matter to decompose fully. Aged clay has two characteristics: 1. It improves and enhances plasticity; 2. It reduces cracking during forming and drying. The longer the clay is aged, the better the quality of the pottery produced. In ancient Chinese Ceramic production, aging the clay was considered a step, with most aging times exceeding one year.

【Firing】

A high degree of firing results in a relatively crisp sound, low water absorption, and a nourished color. Conversely, with a weaker degree of firing, the sound when tapped is duller, the water absorption is higher, and the color is dull without luster. This is because the first firing does not achieve a consistent degree of firing. If the first firing is at a higher degree, the color after subsequent firing will be more lustrous. If the initial degree of firing is lower, the pot may feel slightly “gritty” after subsequent firing, but it is easier to develop a patina.

【Tail Drag】

The tail drag phenomenon occurs mainly due to different particles having varying degrees of softening. During production, the “polishing tool” (a piece of buffalo horn) crushes these particles, causing the tail drag effect. This is more likely to occur with blended clays. When the purple clay particles soften, they are crushed by the polishing tool during production, creating the “tail drag” phenomenon. The purple clay particles in blended clays may turn red or purple at different firing temperatures.

【Black Halo on the Clay】

After prolonged aging, if not handled carefully by the artisan, bottom zaoqing clay can produce black halos on the finished product after firing. Therefore, artisans should thoroughly